Aircraft Mechanics and Asbestos

Aircraft mechanics for military and commercial planes were exposed to airborne asbestos fibers while working with a variety of products installed in aircraft, including asbestos brake pads and heat shields, and products used to protect workers such as asbestos gloves.

Written by Michelle Whitmer • Edited By Walter Pacheco • Legally Reviewed By Yvonne Waterman

Asbestos.com is the nation’s most trusted mesothelioma resource

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

About The Mesothelioma Center at Asbestos.com

- Assisting mesothelioma patients and their loved ones since 2006.

- Helps more than 50% of mesothelioma patients diagnosed annually in the U.S.

- A+ rating from the Better Business Bureau.

- 5-star reviewed mesothelioma and support organization.

Testimonials

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

How to Cite Asbestos.com’s Article

APA

Whitmer, M. (2023, August 30). Aircraft Mechanics and Asbestos. Asbestos.com. Retrieved April 18, 2024, from https://www.asbestos.com/occupations/aircraft-mechanics/

MLA

Whitmer, Michelle. "Aircraft Mechanics and Asbestos." Asbestos.com, 30 Aug 2023, https://www.asbestos.com/occupations/aircraft-mechanics/.

Chicago

Whitmer, Michelle. "Aircraft Mechanics and Asbestos." Asbestos.com. Last modified August 30, 2023. https://www.asbestos.com/occupations/aircraft-mechanics/.

How Aircraft Mechanics Were Exposed to Asbestos

Known within their trade as aircraft maintenance technicians, these mechanics are responsible for grassroots upkeep and safety of U.S. commercial, military and private planes. Commercial and U.S. military aircraft mechanics’ exposure to asbestos was usually the result of direct handling of components during routine repair. Asbestos was used in several parts for its heat and friction resistance.

Repairing brakes gave mechanics the greatest risk of exposure to asbestos, because prior to the 1970s, these brakes were manufactured with asbestos. The replacement of brake pads consists of constant manipulation and tugging back and forth, which most likely exposed workers to airborne asbestos fibers. The collection of fibers, over time, can lead to asbestos-related illnesses.

Because of the heat generated by the engines, mechanics would protect the engine and the test stand with asbestos blankets, which can pose a hazard when they are damaged over time or the fibers are burned off by extreme heat. They also would handle asbestos-containing gaskets in engines and other parts of the aircraft, furthering their exposure.

Other occupations at risk of asbestos-related cancer included those who installed insulation around engines and electrical components. If a part on an aircraft was at risk of catching fire, it was likely insulated with some form of asbestos material. When mechanics cut, sawed, sanded or removed any of these aircraft parts, not only were they exposed to the asbestos in these parts, but also to the asbestos in the adhesives and epoxies holding them together.

A 2009 study in Georgia on airborne asbestos exposure occurring during light aircraft brake replacement did not show alarming levels of asbestos fibers, indicating that repair jobs that were once dangerous to aircraft mechanics because of asbestos exposure do not pose such a threat today.

In the past, the Federal Aviation Administration has issued guidance on asbestos safety to protect workers. In September 2019, it released guidelines on management of asbestos at air traffic organization facilities where old asbestos materials may still be in place. Currently, risk of asbestos exposure is not a major concern for aircraft mechanics working on newer planes. Anyone working on older planes with old parts should take precaution and use personal safety equipment.

Asbestos Products Associated with Aircraft Workers

Asbestos was used all throughout aircrafts, including the engine, cockpit, brake systems and components that held the aircraft together.

Aircraft mechanics were exposed to different types of asbestos products, including:

- Asbestos Gloves, Fabrics, Cloth and Blankets: Mechanics wore asbestos-containing safety gear and used asbestos textiles, including asbestos blankets, to protect from heat and prevent fires.

- Brake Assemblies and Molded Brake Blocks: Repairing brakes was a significant source of asbestos exposure for aircraft mechanics because installing or removing them generated a lot of dust.

- Engine Mounts, Engine Heat Shields, Engine Shrouds: While these products did not generate a lot of dust, they posed an exposure risk when damaged.

- Gaskets, Valves and Other Components: Prior to the 1980s, asbestos was found in several aircraft components, including gaskets, torque valves, refractory fiber felt, cockpit heating systems and tapes used to create seals.

- Repairing Equipment: The equipment mechanics used to repair aircraft prior to the 1980s most likely contained asbestos. These products included adhesives and epoxies, which were used as structural glue.

- Insulation: Electrical insulation, firewall seals, fire sleeves, asbestos sheets, and thermal and acoustical insulation in the cargo bays all posed an exposure risk.

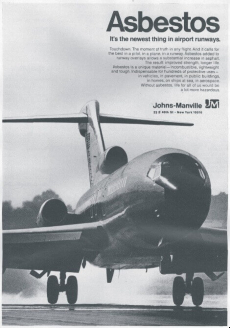

Manufacturers Who Made Products Aircraft Mechanics Use

Several companies made asbestos parts for aircraft in the U.S. until the 1970s and 1980s. These companies are still in business but no longer make asbestos products to avoid liability and litigation.

Manufacturers of asbestos-containing aircraft parts include:

- Cleveland Wheel & Brakes (owned by Parker Hannifin Corporation)

- Fairchild Republic Co.

- Honeywell/Bendix

- Goodyear

- Goodrich

- Johns Manville

- Northrop Grumman

Aircraft Mechanics and Mesothelioma

Aircraft mechanics have developed mesothelioma cancer and other asbestos-related diseases, including lung cancer and asbestosis, as a result of asbestos exposure. According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos.

Mesothelioma is a relatively rare cancer that is almost exclusively caused by asbestos exposure. If you believe you were exposed to asbestos working as an aircraft mechanic, it is important to monitor your health for signs of lung or digestive problems. If you develop symptoms such as difficulty breathing or abdominal bloating, seek the advice of a specialist and request an asbestos cancer screening.

Diagnosing and treating asbestos-related diseases early improves chances of long-term survival. It is important to find a doctor specializing in your diagnosis to access the best possible care.

Compensation for Aircraft Workers Exposed to Asbestos

Aircraft workers have successfully sued manufacturers of asbestos aircraft products that caused them to develop mesothelioma and other diseases. Most of these lawsuits go unreported in the news, but they continue to be filed today.

Manufacturers of asbestos aircraft parts, including Johns Manville, tried to hide their knowledge of the dangers of asbestos from workers and consumers. Mesothelioma lawsuits uncovered internal company documents revealing that these companies knew of the health risks of asbestos and chose to use it anyway.

If you’ve been diagnosed with an asbestos-related disease you may be eligible for compensation. A mesothelioma lawyer has the expertise to review your case and guide you on the types of claims you may qualify to file, including asbestos trust fund claims, personal injury lawsuits and wrongful death lawsuits.

- For example, in 2016, a Florida jury awarded $9 million to a woman who developed mesothelioma through exposure to asbestos on her husband’s clothes. Her husband worked for aircraft manufacturer Northrup Grumman.

- In 2011, a California court granted in part and denied in part a summary judgement filed by Parker Hannifin Corporation, a defendant in a mesothelioma lawsuit filed by Jenny Bowser, the wife of former aircraft mechanic Gerald Bowser, who died of mesothelioma. She blamed her husband’s exposure on asbestos-containing aircraft brakes distributed under the brand name Cleveland Wheel & Brakes, which were produced by a predecessor of Parker Hannifin. The outcome of this case and whether the parties reached a settlement has not been published.