When filing a mesothelioma claim, the right legal representation is everything. We’ll connect you to a top lawyer who will help you secure financial compensation.

Find an AttorneyAsbestos plant workers encountered the toxic mineral in every part of their job. Researchers studying one asbestos plant found the risk of dying from asbestos-related diseases increased nearly 250%. The longer the exposure, the more asbestos fibers accumulate in lung tissue.

All work performed in an asbestos factory endangered worker health. These plants had such high levels of asbestos circulating around the plant that every corner of the facility posed an exposure risk.

A 2020 study of eight asbestos processing plants in China found an increased incidence of mesothelioma in the population of those who lived near the plants.

In 2016, the Journal of Toxicology and Environmental Health published a study on 1,130 people who worked at an asbestos plant in Tyler, Texas, from 1954 to 1972. Researchers found that working at the plant increased a worker’s risk of dying from throat or lung cancer by 244%.

Asbestos plant workers were exposed at every step of the manufacturing process:

When filing a mesothelioma claim, the right legal representation is everything. We’ll connect you to a top lawyer who will help you secure financial compensation.

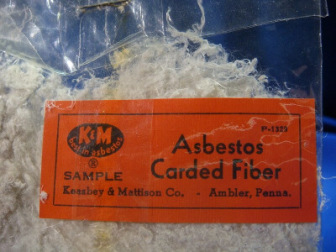

Find an AttorneyAsbestos plants produced carded asbestos fibers, asbestos yarn and asbestos rope.

Carded asbestos fibers were sold to many different industries manufacturing asbestos products that ranged from insulation to adhesives to asbestos cement pipes. Different geologic sources of asbestos became known as certain brand names of asbestos fibers. For example, Union Carbide trademarked its asbestos from a mine in California as “Calidria asbestos.” The company sold different grades of asbestos fibers, including Resin Grade 244, which was so fine workers reported that it floated in the air during production.

Asbestos yarn was sold to textile mills that manufactured a wide variety of products, including gloves for firefighters, fireproof curtains for movie theaters and heat-resistant ironing pads. Asbestos yarn was also used to make air conditioning duct connectors, pipe coverings, welder’s blankets and electrical cloth.

Asbestos rope was used as a packing material and served as a gasket material in industrial settings. It was used in pumps, compressors, seals and throughout ships for its resistance to heat and chemical corrosion.

Some asbestos mining operations owned asbestos plants to process the ore for sale. In the Eastern United States alone, 60 asbestos mines were in operation from the 1800s through 1993. Information on where the ore from these mines was processed is difficult to find.

Some asbestos plants sourced their asbestos from Canada, including Keasbey & Mattison. The company sourced its asbestos from Thetford Mines in Quebec and processed it in Ambler, Pennsylvania. Ambler now has some of the highest rates of mesothelioma and asbestos-related disease in the country.

The following companies operated asbestos plants in the United States:

Studies show an increased incidence of asbestos-related diseases among industrial factory workers such as those in asbestos plants. According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos.

In a 2015 study of asbestos processing plant workers from Normandy, France, researchers found excess cases of esophageal cancer, liver cancer, colorectal cancer, peritoneal mesothelioma and other digestive cancers.

A 1998 study by the National Institute for Occupational Safety and Health led the agency to warn asbestos textile, friction and packing plant workers about the health risks associated with their occupations. The study found asbestos plant workers died of lung cancer at nearly double the rate of the general population.

Seventeen study participants died from mesothelioma, which is a form of cancer almost exclusively caused by asbestos exposure. Asbestosis, which is a scarring of the lung tissues, caused an additional 90 deaths in the study group when 17 deaths were expected based on the general population. The study also showed an increased incidence of death from heart disease among asbestos plant workers, which is likely because lung problems frequently lead to heart issues.

Family members of plant workers exposed to asbestos at work also developed asbestos-related diseases because workers unknowingly carried home asbestos fibers on their clothes, shoes, skin and hair. This kind of secondary exposure can cause mesothelioma and other asbestos-related diseases.

People who lived around asbestos plants also suffered higher rates of asbestos-related illness even if they or a family member never worked at the plant. This kind of exposure is known as environmental exposure because plant operations led to contamination of ambient air in the community.

Working with a doctor specializing in mesothelioma or lung cancer treatments is important for improving your chances of long-term survival. The prognosis for these conditions is poor. Most people live around one year with mesothelioma or lung cancer. Finding a specialist at a top treatment center could help you live longer with these incurable diseases.

You shouldn’t have to choose between getting care and paying for it. Get the financial support you deserve.

Explore Your OptionsMost asbestos plants that operated in the U.S. shut down between the 1970s and 1990s. An exception is the Coalinga mine and processing plant in California, which was operated by King City Asbestos Company and closed in 2002. Many workers who developed asbestos-related illnesses have successfully sued the companies that operated these plants and supplied asbestos fibers to various industries.

An experienced mesothelioma lawyer has the expertise to review your case and advise you on the types of claims for asbestos exposure you may qualify to file. In addition to a personal injury lawsuit or wrongful death claim, you may also qualify to file claims with asbestos trust funds.

Recommended ReadingStay up-to-date on treatment, research, clinical trials, doctors and survivors

The information on this website is proprietary and protected. It is not a substitute for professional medical advice, diagnosis or treatment. Any unauthorized or illegal use, copying or dissemination will be prosecuted. Please read our privacy policy and terms of service for more information about our website.

This website and its content may be deemed attorney advertising. Prior results do not predict a similar outcome.

The Mesothelioma Center’s claim as the most trusted resource is based on our more than 150 5-star Google and BBB reviews. Our organization also helps more than half of all mesothelioma patients annually diagnosed.

Your web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Whitmer, M. (2026, February 12). Asbestos Plant Workers and Mesothelioma. Asbestos.com. Retrieved February 19, 2026, from https://www.asbestos.com/occupations/asbestos-plant-workers/

Whitmer, Michelle. "Asbestos Plant Workers and Mesothelioma." Asbestos.com, 12 Feb 2026, https://www.asbestos.com/occupations/asbestos-plant-workers/.

Whitmer, Michelle. "Asbestos Plant Workers and Mesothelioma." Asbestos.com. Last modified February 12, 2026. https://www.asbestos.com/occupations/asbestos-plant-workers/.

An occupational scientist or another expert who specializes in occupational hazards reviewed the content on this page to ensure it meets current scientific standards and accuracy.

Arti Shukla, Ph.D., is an internationally renowned asbestos researcher known for her achievements in identifying biomarkers that cause mesothelioma. She is the director of the Shukla Research Lab, as well as a professor of pathology at The University of Vermont Larner College of Medicine.

Our fact-checking process begins with a thorough review of all sources to ensure they are high quality. Then we cross-check the facts with original medical or scientific reports published by those sources, or we validate the facts with reputable news organizations, medical and scientific experts and other health experts. Each page includes all sources for full transparency.

Please read our editorial guidelines to learn more about our content creation and review process.