Insulators and Asbestos Exposure

Insulators are employed in many fields and are responsible for installing and replacing insulation material to control and maintain the temperature. Exposure to asbestos insulation is a significant health hazard for insulation workers in older residential and industrial settings.

How Are Insulators Exposed to Asbestos?

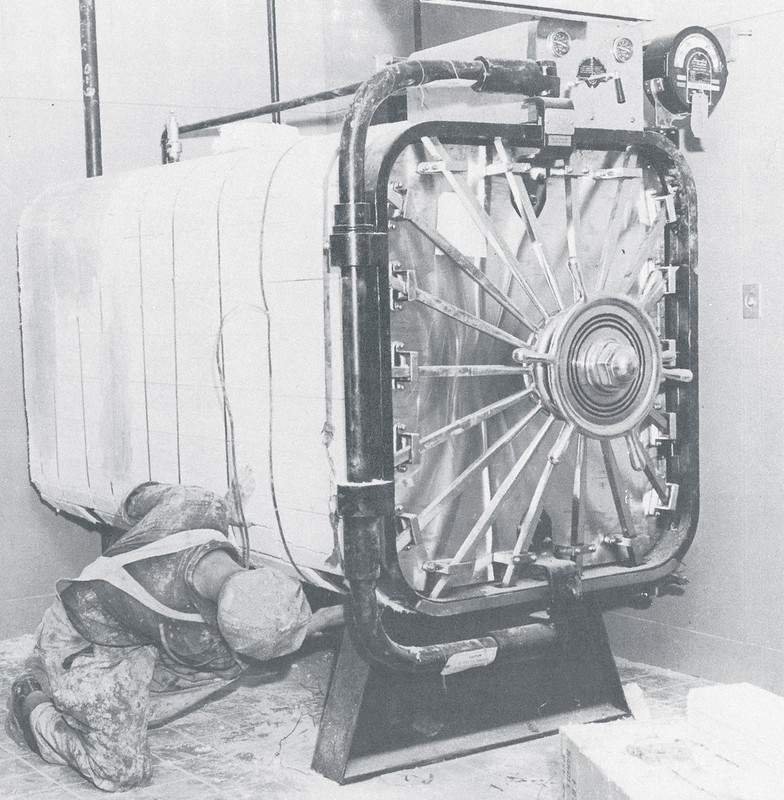

Tradespeople known as insulators had constant exposure to asbestos-laden materials, putting them at risk of developing mesothelioma. Insulators worked directly with asbestos products, installing, repairing and removing insulation on pipes, boilers and ducts. They cut, sanded or tore asbestos materials to size.

These actions created clouds of dust. Workers inhaled asbestos fibers as they became airborne. The materials appeared harmless, and many didn’t use any protective gear. As a result, the rate of pleural mesothelioma for insulators was more than 10 times higher than the rate for the general population rate.

The height of asbestos use was before 1980, but legacy asbestos remains a threat today. Insulators may find themselves exposed while working in older buildings, often without proper testing and remediation of materials. Not only can insulators be in danger, but their family members may also be at risk of asbestos exposure. Asbestos fibers can cling to an insulator’s work attire and expose family members at home.

Asbestos Products Insulators Used

Insulators often handled asbestos products directly. These materials prevented heat loss and reduced fire risk but can be inhaled when disturbed. Inhaling asbestos fibers is the main cause of mesothelioma.

Asbestos Insulation Products

Blanket insulation: Flexible sheets that wrap around ducts, piping and mechanical systems.

Block insulation: Pre-formed blocks are used to insulate walls, tanks and large mechanical systems.

Cement and plaster mixtures: Used as coatings and fillers around joints, fittings and structural components.

Pipe and boiler insulation: Used to cover high-temperature pipes and boilers in industrial and commercial buildings.

Spray-on insulation: Applied to ceilings and walls to provide thermal insulation and fireproofing.

Zonolite insulation: Well-known asbestos brand for HVAC systems, used as loose-fill in attics and walls.

Insulators used these materials across construction sites, industrial plants and shipyards. Even a small amount of airborne asbestos could cause long-term health problems. In addition to mesothelioma, asbestos can cause a number of asbestos-related diseases such as lung cancer, asbestosis, COPD and pleuritis.

Manufacturers of Products Insulators Used

Well-known companies manufactured many insulation products that included asbestos. These companies continued to sell them long after knowing the risk of mesothelioma that workers faced as a result of asbestos exposure.

Companies That Made Asbestos Insulation

The manufacturers of asbestos products put insulators and their families at risk. Some of these manufacturers faced lawsuits. As a result of mounting litigation, a number of them declared bankruptcy. In that process, manufacturers created asbestos trust funds to pay future claims to exposed workers.

Get help finding a top attorney who can get you the compensation you deserve.

Get Help NowInsulators and Mesothelioma

Research shows insulators are among the highest-risk workers for mesothelioma and other asbestos diseases. Inhaling asbestos fibers over time can cause them to accumulate in tissue in your body. Irritation and inflammation can occur, and eventually, this can begin to change the DNA of cells to become cancerous.

A study published in February 2025 in Occupational & Environmental Medicine reports asbestos insulation workers were at a particularly high risk of asbestos-related cancers. The study authors concluded, “The meta-analyses support a causal link between occupational asbestos exposure and the risk of oesophageal, stomach and colorectal cancer.”

A 2023 study found 95.2% of insulators had definitive occupational exposure to asbestos, averaging 30.9 years. Previous global studies found significant mortality rates from past asbestos exposure and rates of pleural mesothelioma more than 10 times higher than in the general population among insulators. Studies also confirm that many insulation workers still face asbestos exposure today.

Many people diagnosed with mesothelioma are retired insulators who worked decades ago. Because the disease can take 20 to 60 years to appear, even short-term occupational exposure long ago may lead to illness today.

Compensation for Exposed Insulators

If you worked as an insulator and have mesothelioma or another asbestos-related disease, you may qualify for compensation. Mesothelioma claims can help cover treatment, travel costs and other expenses. In 2009, a Tennessee jury awarded the family of a pipefitter $1.4 million in a wrongful death lawsuit.

One woman developed mesothelioma from secondhand asbestos exposure while washing her husband’s work clothes contaminated with CertainTeed products. A Los Angeles jury awarded her $208.8 million in April 2010.

Types of Mesothelioma Compensation

- Asbestos trust fund claims

- Personal injury lawsuits

- VA benefits (for military service)

- Workers’ compensation

Claim amounts vary, but many trust fund payouts range from $30,000 to more than $300,000, depending on the level of exposure and the diagnosis. Some insulators have received settlements after proving they worked around known manufacturers’ asbestos materials.

Filing a claim doesn’t affect your ability to receive medical care or other benefits. A mesothelioma lawyer can help determine which options apply to your case.

Recommended Reading