Steel Mill Workers and Asbestos

Steel mill workers faced many health hazards, including exposure to asbestos in insulation, gaskets, boilers, brakes and protective gear. As a result of this exposure, steel mill workers suffer higher rates of mesothelioma and other asbestos-related diseases.

Written by Michelle Whitmer • Edited By Walter Pacheco • Legally Reviewed By Yvonne Waterman

Asbestos.com is the nation’s most trusted mesothelioma resource

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

About The Mesothelioma Center at Asbestos.com

- Assisting mesothelioma patients and their loved ones since 2006.

- Helps more than 50% of mesothelioma patients diagnosed annually in the U.S.

- A+ rating from the Better Business Bureau.

- 5-star reviewed mesothelioma and support organization.

Testimonials

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

How to Cite Asbestos.com’s Article

APA

Whitmer, M. (2023, October 3). Steel Mill Workers and Asbestos. Asbestos.com. Retrieved April 18, 2024, from https://www.asbestos.com/occupations/steel-mill-workers/

MLA

Whitmer, Michelle. "Steel Mill Workers and Asbestos." Asbestos.com, 3 Oct 2023, https://www.asbestos.com/occupations/steel-mill-workers/.

Chicago

Whitmer, Michelle. "Steel Mill Workers and Asbestos." Asbestos.com. Last modified October 3, 2023. https://www.asbestos.com/occupations/steel-mill-workers/.

How Are Steel Mill Workers Exposed to Asbestos?

Asbestos was used in steel mills as a common insulation material from the 1940s through the end of the 1970s. As a result, workers were exposed to this toxic material while performing their daily tasks. Asbestos exposure remains a danger for those working in buildings built before the 1980s or using equipment of that era, because many of the asbestos parts haven’t been replaced with non-asbestos materials.

Maintenance workers, machinists, pipefitters and boiler workers faced the highest risk of asbestos exposure in steel mills. Welders, blacksmiths, bricklayers, millwrights and motor inspectors also encountered asbestos on a regular basis. Regardless of the type of steel mill worker, exposure to asbestos was usually the direct result of handling machinery, equipment and material in the process of manufacturing steel.

Asbestos insulation was used in an abundance of steel mill equipment because it helped prevent fires and burns. This included ovens, hot blast stoves, furnaces, rolling mills, tanks, boilers, cranes, molding boards and steam pipes. Workers would inhale these asbestos fibers during the steel manufacturing process while feeding vessels scrap metal by crane, controlling machinery to melt the scrap metal, and adding other metal to give it the required chemical composition.

Workers in steel mills often wore asbestos protective garments, including coats, leggings, gloves, aprons, coveralls and face masks, to protect them from extreme temperatures and from burns while working with molten materials. After daily wear and tear on these protective garments, fibers within the clothing were released and could be inhaled by workers. Through regular use, clothing was also susceptible to cuts by pieces of sharp metal or machinery, which released extra fibers.

Steel mill workers were also exposed to asbestos particles even if they were not participating in the actual manufacturing of steel because so many materials contained asbestos. This included asbestos blankets used for covering ladles, which were often discarded on the pouring pit floor; building material such as refractory bricks on hot tops; floor and ceiling tiles; and liner boards.

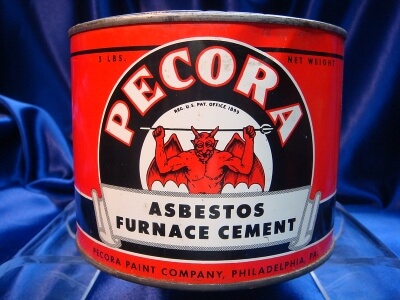

Asbestos Products Associated with Steel Mills

Steel mill workers handled a wide range of asbestos products that prevented fires and injuries from the extremely high temperatures common in their workplace.

- Construction Materials

Asbestos-containing materials used in steel mills include floor tiles and ceiling tiles, liner boards and refractory bricks on hot tops. Asbestos cement was also a versatile building material found in steel mills.

- Insulation

Asbestos insulation could be found in equipment such as ovens, hot blast stoves, furnaces, rolling mills, tanks, boilers, cranes, molding boards and steam pipes. Asbestos packing, pipe wrap insulation and asbestos cement were among the most common forms of asbestos insulation in steel mills.

- Machine Parts

Brake pads, clutches, gaskets, valves and pumps all contained asbestos fibers to control heat and prevent damage to parts that had to withstand high temperatures.

- Protective Gear

Asbestos-containing materials were used in protective clothing such as gloves, aprons, coveralls and face masks. Employees who worked with furnaces and stood along the paths where molten metal flowed wore asbestos coats and leggings during the casting process.

Manufacturers of Products Steel Mill Workers Used

The following manufacturers using asbestos in products produced asbestos materials that were handled by steel mill workers.

- Foseco: Foseco made several asbestos products that it sold to foundries and steel mills, including ladle liners, furnace linings, hot top insulation, insulating boards and coatings.

- GAF Corp.: Asbestos products made by GAF were used in steel mills, including coatings, insulating cement, pipe coverings and boiler insulation.

- Guard-Line Inc.: Asbestos gloves used by steel mill workers were made by Guard-Line.

- Johns Manville: JM made numerous asbestos-containing construction materials, including roofing, flooring and walling materials, which were used to construct industrial job sites such as steel mills.

- Keystone Steel & Wire Co.: Keystone manufactured asbestos products such as boiler insulation that steel mill workers encountered.

- Owens-Illinois Inc.: This company manufactured Kaylo brand asbestos block insulation and pipe coverings that were installed in steel mills.

- Porter Hayden Co.: Porter Hayden was a former installer of asbestos-containing insulation inside steel mills.

- Steel Grip: Asbestos gloves and shoe coverings used by steel workers were made by Steel Grip.

Steel Mill Workers and Mesothelioma

When workers inhaled asbestos fibers, some would become lodged in the lungs and pleural lining of the lungs, often causing scarring and damage that led to tumor formation later in life. Many workers were eventually diagnosed with mesothelioma cancer.

According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos. Medical researchers have conducted a number of scientific studies related to asbestos in steel mills.

- A study published in 2019 analyzed asbestos fiber concentrations that were collected from 1972 to 1982 in steel mills. Asbestos was detected when steel mill bricklayers and their helpers relined open-hearth furnaces, stoves and blast furnaces.

- In 2015, a British Medical Journal study reported asbestos-related deaths in Belgian workers. Based on data from 2001-2009, metal manufacturing workers are almost three times more likely to die of mesothelioma than the general population.

- A 2010 study of steel workers in Belgium found an increased prevalence of asbestos disease, particularly among maintenance workers and production workers. In seven cases autopsied, a mesothelioma diagnosis was confirmed. The asbestos fiber burden analyses showed a range of concentrations between 260,000 and 11,000,000 fibers per gram of dry tissue. The highest fiber burden was detected in the maintenance workers of the same plant in which a cluster of malignant mesothelioma was observed.

- In the late 1970s, research conducted by Dr. William J. Blot revealed cases of asbestosis among pipe coverers working in steel mills.

Diagnostic testing for asbestos-related diseases involves imaging scans, biopsies and blood tests. Occupational histories are crucial for doctors when considering asbestos-related illnesses, so make sure to fully describe your asbestos exposure history.

It’s important to find a mesothelioma specialist to guide your treatment plan. These doctors have spent years specializing in mesothelioma and have the best experience to manage your cancer care. They can also connect you with the latest innovative clinical trials.

Legal Options for Steel Mill Workers Exposed to Asbestos

Steel mill workers have successfully sued manufacturers of asbestos products and steel mills such as AK Steel, USX Corporation, LTV Steel, Weirton Steel and Wheeling-Pittsburgh Steel Corp. They’ve filed personal injury lawsuits and made claims with asbestos trust funds. Family members who lost a loved one have filed wrongful death claims as well.

- In 2010, a jury awarded the family of Barry Baumener $2 million after he died from mesothelioma. The company found responsible for his exposure to asbestos was Oglebay Norton Co., which supplied asbestos-containing products to the steel mill where Baumener worked. In addition to the $2 million received from Oglebay Norton, Baumener’s family settled with 24 other companies for an undisclosed amount of money.

- Roby Whittington won a $250 million verdict from a Madison County, Illinois, jury in 2003 through his lawsuit against U.S. Steel. From 1950 to 1981, Whittington worked for U.S. Steel’s Gary Works plant in Gary, Indiana. In 2001, he was diagnosed with mesothelioma, which he attributed to his job at the steel plant. The plant used asbestos-containing insulation as a fire retardant. U.S. Steel reportedly settled the suit for an undisclosed amount of money instead of appealing the verdict.

If you’re a steel mill worker diagnosed with mesothelioma, it is in your best interest to find an experienced mesothelioma lawyer to handle your claim. Steel mill asbestos cases are a complex area of asbestos litigation that should only be managed by an experienced lawyer.