Industrial Workers and Asbestos Exposure

Industrial workers are specialized production mechanics, foremen and tradespeople exposed to asbestos in their protective gear and asbestos products during manufacturing. Today, the risk exists from older machine parts and construction materials used in building the plants.

Written by Sean Marchese, MS, RN • Edited By Walter Pacheco • Scientifically Reviewed By Arti Shukla, Ph.D.

Asbestos.com is the nation’s most trusted mesothelioma resource

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

About The Mesothelioma Center at Asbestos.com

- Assisting mesothelioma patients and their loved ones since 2006.

- Helps more than 50% of mesothelioma patients diagnosed annually in the U.S.

- A+ rating from the Better Business Bureau.

- 5-star reviewed mesothelioma and support organization.

Testimonials

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

How to Cite Asbestos.com’s Article

APA

Marchese, S. (2024, March 25). Industrial Workers and Asbestos Exposure. Asbestos.com. Retrieved April 18, 2024, from https://www.asbestos.com/occupations/industrial-workers/

MLA

Marchese, Sean. "Industrial Workers and Asbestos Exposure." Asbestos.com, 25 Mar 2024, https://www.asbestos.com/occupations/industrial-workers/.

Chicago

Marchese, Sean. "Industrial Workers and Asbestos Exposure." Asbestos.com. Last modified March 25, 2024. https://www.asbestos.com/occupations/industrial-workers/.

How Are Industrial Workers Exposed to Asbestos?

Industrial workers include mechanics, forepersons and trade laborers, who handle the manual labor associated a variety of occupations. Welders, molders, millwrights and smelters are all examples of industrial workers.

These workers often repair machinery or operate power and heat systems. Most industrial processes generate heat, and many manufacturers added asbestos to their products due to its insulating properties.

When repairing or operating machinery made with asbestos products, the disturbance generated dangerous dust that placed workers at risk for a number of serious diseases. The occupational exposure hazards worsened when they used power tools for scoring, drilling, grinding or cutting.

A 2015 study published in Occupational Environmental Medicine calculated the risk of asbestos-related cancer for different professions. The researchers estimated that industrial workers are over four times more likely to develop pleural mesothelioma than the general population.

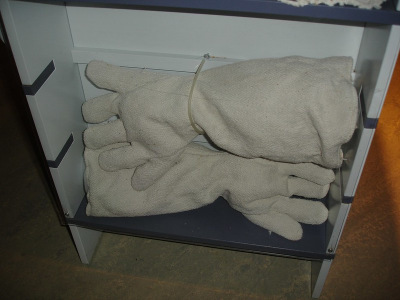

Laborers may also have worn asbestos-contaminated protective gear during specific tasks. Gloves and other protective products often included flame-retardant, asbestos-treated cotton. Workers also used raw asbestos in mixtures with gypsum slurry for production molds.

Most industrial plants had inadequate ventilation systems. Airborne fibers tended to circulate throughout the workspace for extended periods; this further increased the workers’ risks of occupational exposure.

Asbestos Products Associated with Industrial Workers

According to the Fourth National Forum for Asbestos Litigation, nearly every company that owned or maintained conventional industrial plants before the 1970s may have allowed asbestos products on their premises.

These products included construction materials such as floor or ceiling tiles and insulation for machinery and equipment. Workers were also regularly exposed to asbestos-containing textiles and raw asbestos during daily operations.

Protective Gear Industrial Workers Used

Gloves: To prevent workers from burns, textile manufacturers made gloves with asbestos-treated cotton, making them heat-resistant and fire-retardant.

Aprons: Welders, smelters and other metalworkers wore aprons made with asbestos which protected them from embers and molten metal.

Clothing: Factory workers often wore fire-proof jackets or pants made with asbestos fibers. Over time, the frayed clothing would release breathable asbestos fibers into the air.

Asbestos Machine Parts & Construction Materials

Gas Valves: Asbestos in gas valves prevented overheating when hot gases would pass through.

Autoclaves: Workers used autoclaves for sterilization or processing. Autoclaves superheat tools and materials and relied on asbestos to control temperatures.

Engine Heaters: Manufacturers used asbestos for engine heating products, heated surfaces and metal structures, which frequently involved spray-on insulation.

Construction Products: Industrial workers often operated in proximity to construction products and materials made with asbestos, including floor tiles, ceiling tiles, insulation and cement.

Products Industrial Workers Used and Manufactured with Asbestos

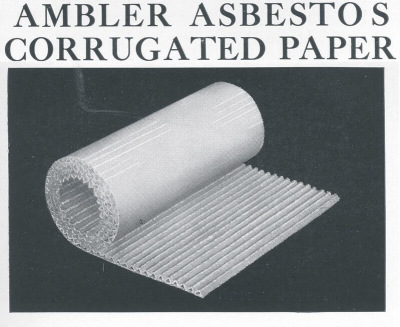

Asbestos Paper: Manufacturers using asbestos in products often stocked their goods at industrial sites for workers. A common material was asbestos paper used in wraps and packing.

Asbestos Textiles: Workers often used rope lagging and braided packing made with asbestos and recommended for high-speed rotary and reciprocating shafts or hot water machinery.

Metal Work: In addition to using raw asbestos in metal molds and casts, workers involved in hammering, soldering, melting and sandblasting all contributed to increased asbestos exposure and health risk. That danger extended to smelting, refining, forging, welding and stamping.

Manufacturers Who Made Products Industrial Workers Use

Many industrial product manufacturers have produced asbestos-containing products. Notable companies involved with asbestos litigation include:

Vulcan Iron Works Inc.: Based in Pennsylvania, Seattle and San Francisco, Vulcan produced steam locomotives, boilers, engines and mining machinery.

Eastern Refractories Company: In 2004, a journeyman insulator claimed Eastern was responsible for his mesothelioma after years of working with their ERCO-Mat product.

AK Steel Corporation: Previously one of the largest metalworking companies in the U.S., AK Steel produced products and machinery used by industrial workers.

Riley Stoker Corporation: Founded in 1890, Riley Stoker manufactured boilers and repair parts that contained asbestos.

Sterling Fluid: After receiving a mesothelioma diagnosis in 2011, William L. Pace sued Sterling for years of asbestos exposure from their gaskets, pumps and valves.

Westinghouse: Westinghouse has faced asbestos litigation several times for using asbestos in welding rods, lightbulbs, turbines and other products. Afton Pumps: In 2018, Timothy and Wendy Thomas sued Afton Pumps for asbestos exposure after Timothy’s career as a pipe and sprinkler fitter led to his lung cancer.

Industrial Workers and Mesothelioma

According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos.

A 2018 study pointed to the iron and steel industries as one of the highest risk sources for occupational asbestos exposure. Workers in iron and steel industries had comparable rates of mesothelioma with those in other primarily asbestos-using industries.

A German study published in 2016 reported high clusters of malignant mesothelioma patients with backgrounds in shipyard and steelwork. Between 2009 and 2013, German cancer registries reported 7,547 malignant mesothelioma cases, with 90% involving the pleura.

The risk of asbestos exposure was analyzed by occupational group in one study. Welders, millwrights, sheet metal workers, laborers and maintenance workers sustained serious exposure levels, but industrial insulators were the most at risk.

Mt. Sinai School of Medicine studied the asbestos-related disease risks for industrial machinists in a 1993 study. About 44% of the 110 workers in the study had pleural abnormalities that were consistent with asbestosis, pleural thickening and interstitial lung disease.

Legal Options for Industrial Workers Exposed to Asbestos

According to the research firm RAND, an estimated 90% of the industrial occupations recognized by the U.S. Department of Commerce have been defendants in asbestos lawsuits.

One welder received a $1.29 million verdict against the Hobart Brothers Company, a manufacturer of asbestos-containing welding rods. The plaintiff used the rods at a metal fabrication company for 30 years and died from asbestos lung cancer.

A similar trial involved former welder and sheet metal mechanic Donald Perman. Perman worked with asbestos products at American Sheet Metal for 12 years, and wore protective gear made with asbestos. He died before his case went to trial.

Industrial workers may seek compensation by filing claims with an experienced mesothelioma attorney. Some employees choose to pursue workers’ compensation.

Thomas Baptiste, a millright, claimed asbestos dust contaminated his workspace. His job was to repair gearboxes and cranes, weld metals and assemble asbestos gaskets. Baptiste was diagnosed with multiple respiratory diseases, including lung cancer and asbestosis. An appeals court allowed Baptiste his worker’s compensation claim.