Most buildings constructed between 1930 and 1980 contained asbestos insulation. Some buildings still contain high levels of asbestos. Construction workers and homeowners face potentially serious health consequences from continued exposure to asbestos wall, basement and attic insulation.

Asbestos insulation is a building material that contains asbestos. This toxic, natural mineral can cause mesothelioma and lung cancer. It can also cause other serious diseases. There are many types of asbestos insulation: block, loose fill, spray-on and wrap.

Asbestos insulation was common in buildings until the late 1970s. The unique physical characteristics of its fibers make asbestos resistant to heat.

Businesses eventually had to phase out asbestos. Federal regulations limited its use. However, many older buildings still contain asbestos materials that pose health risks.

The most notable U.S. companies that made asbestos insulation are Johns Manville and W.R. Grace & Co. Many asbestos insulation companies filed for bankruptcy after lawsuits targeted them.

Asbestos Insulation Companies

Establishing a trust fund is a common component of the bankruptcy process. Johns Manville, Owens Corning, National Gypsum and W.R. Grace all have trust funds. Former workers and others exposed to their products can seek compensation from these funds. It can cover medical and related expenses.

Several brands have a link to asbestos insulation. These companies made much of the materials used in homes and businesses. Some are more widely known than others.

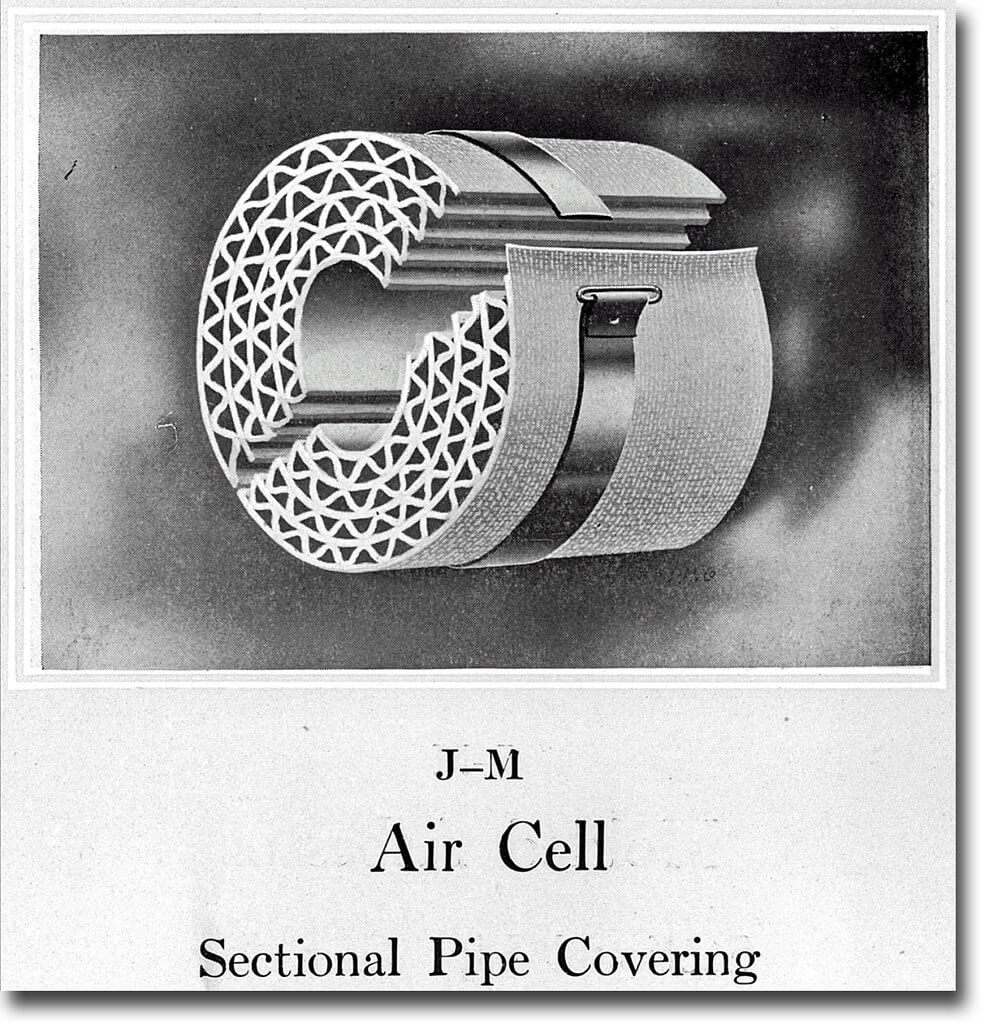

Air Cell, Marinite, Superex and Thermobestos were asbestos insulation brands from Johns Manville, which is among the most well-known asbestos-related companies.

Nicolet Keasbey & Mattison also had a brand of pipe insulation called Air Cell. The company was once one of the world’s largest asbestos producers. It made industrial products, including Hy-Temp insulation, from its Ambler, Pa., headquarters.

Armstrong Contracting and Supply brands of asbestos insulation included Armatemp and Hi-Temp. Products included insulating roof tiles, block, pipe and felt insulation.

Celotex brands include Careytemp, Carey Thermalite and Vitricel. Celotex was a major manufacturer of asbestos roofing, siding and insulation for buildings. It also owned asbestos mines.

Materials bearing the popular Gold Bond brand were among National Gypsum’s asbestos brands. The company was a major producer of asbestos wallboard, roofing and ceiling panels.

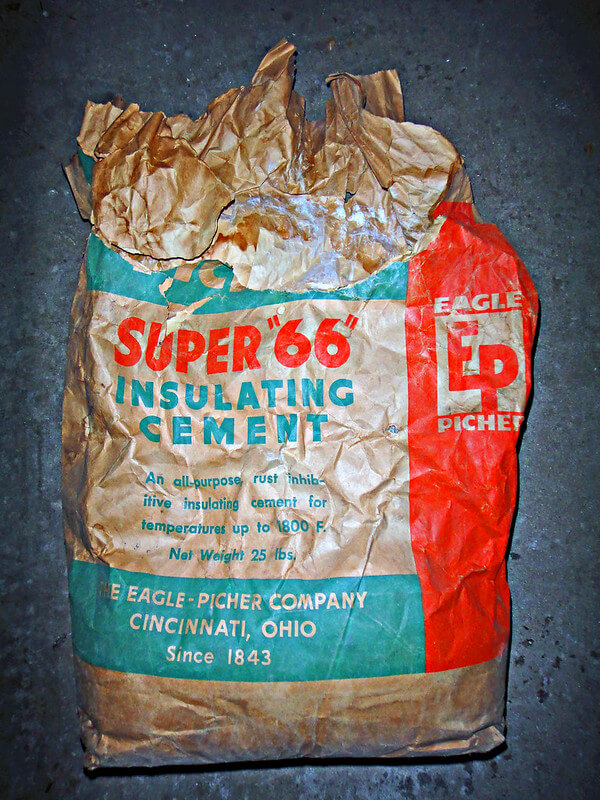

Hylo Block, Supertemp Block and Super 66 insulating cement are all brands from manufacturer EaglePicher Industries Inc. The company made asbestos insulation. It was widely used in military applications.

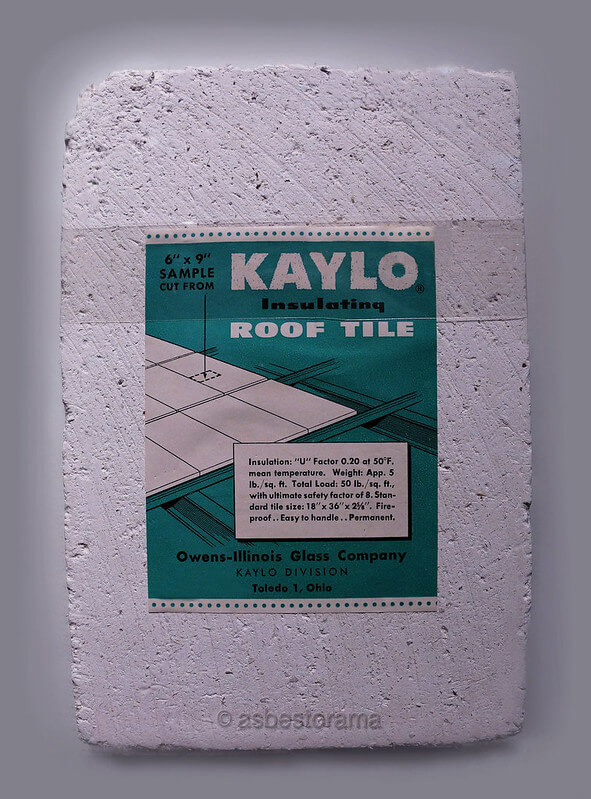

Owens Illinois Glass Company produced Kaylo pipe and block insulations. They contained up to 20% asbestos.

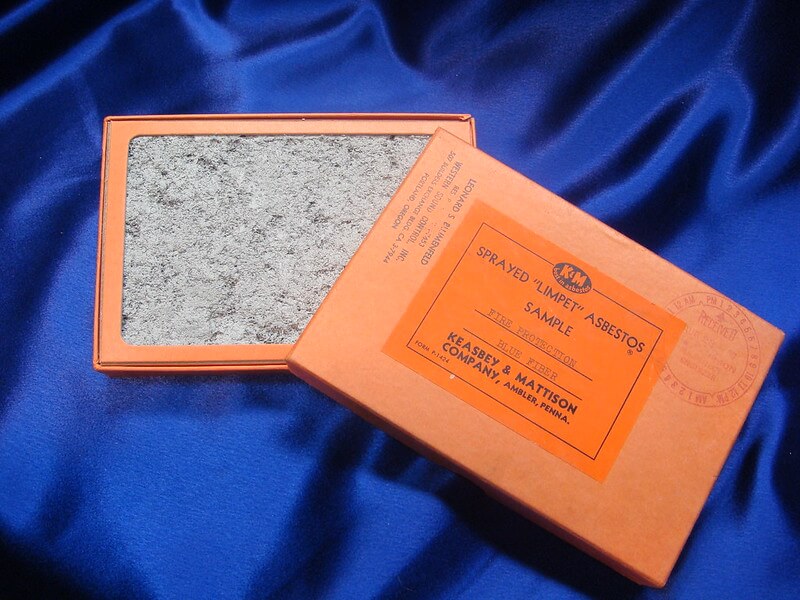

Turner and Newall, a U.K. company, made many asbestos products. These included the widely used Limpet spray that contained 85% asbestos. Keasbey & Mattison was sold to Turner and Newell in 1934. Armstrong Contracting and Supply had an exclusive license to distribute Limpet Asbestos in the U.S. from 1962 to 1967.

Zonolite and Monokote were brands from asbestos manufacturer W.R. Grace. The company’s mines were once responsible for a large portion of the world’s asbestos products.

Many other companies also used asbestos in insulation and other building materials. As a result, their workers and product end users were exposed to asbestos fibers over long periods. This contributed to a large number of lawsuits. Many asbestos companies set up trust funds to handle these claims.

There are several types of asbestos insulation with varying uses ranging from construction to industrial applications. The four main types are block, loose-fill, spray-on and wrap.

Additionally, these insulation products use more than one type of asbestos. The exact structure of the mineral determines its best use. Types of asbestos include amosite, anthophyllite, chrysotile, crocidolite, tremolite and actinolite.

Other types of asbestos insulation include cement, plaster and electrical panels. Some batt insulation products also contain it. Combined, these forms of asbestos contributed to the widespread exposure of workers and their household members. Many people faced exposure to multiple asbestos products in manufacturing, construction and other trades.

Reaching peak use in the 1960s, Zonolite insulation was made by W.R. Grace. The company made Zonolite using vermiculite from its mine in Libby, Montana. It was contaminated with tremolite asbestos.

Documents from the U.S. Environmental Protection Agency estimate that some 30 million homes may still have Zonolite in their attics. Because it’s hazardous even at low levels, Zonolite asbestos insulation poses a risk to residents who are unaware of the danger.

Asbestosfluf asbestos attic insulation is a loose-fill product. It was popular in Australia in the 1960s and 1970s. Its manufacturer was commonly known as Mr. Fluffy because of the product’s cottony appearance.

In the 1980s, the Australian government ran a campaign to remove Asbestosfluf insulation from homes. It knew the material was dangerous. However, the product’s dust was everywhere. Even homes with all asbestos removed were contaminated.

Julie K. has survived more than 30 years since her pleural mesothelioma diagnosis. She believes her diagnosis was the result of asbestos exposure when she was a child. Her father was an electrical engineer who used to bring home asbestos insulation to wrap around the radiator pipes they used to heat the older house where she grew up. The head of Julie’s bed was adjacent to the heater.

Asbestos insulation can cause serious diseases including mesothelioma and asbestos lung cancer. The body struggles to break down and expel asbestos fibers. When inhaled, they can build up in the lungs, causing inflammation, scarring and other damage.

Asbestos fibers cause the root of mesothelioma and asbestos-related lung cancer. Asbestos fibers get lodged in the pleural lining of the lung and inflammation and genetic changes happen.

Other major health problems are also linked to asbestos exposure. Asbestos-related diseases include ovarian cancer, laryngeal cancer and asbestosis.

Most asbestos diseases are related to occupational exposure in fields like mining, construction and manufacturing. Workers inhaled asbestos fibers while working around it for long periods. The duration of exposure increases the risk of getting sick.

Workers Who Encounter Asbestos Insulation

Asbestos is no longer used in residential construction. It is still used in some industrial applications, though. As a result, some workers still face asbestos exposure today. Firefighters, insulators and military members remain at risk.

Learn about your diagnosis, top doctors and how to pay for treatment.

Get Your Free GuideThose harmed by asbestos can seek compensation from insulation makers. Many of them have established trust funds to pay legal awards.

Many companies created unsafe products or working conditions. Juries have awarded punitive damages to workers who develop diseases from these actions.

Notable Asbestos Verdicts

If you or a loved one was exposed to asbestos at work, contact an experienced asbestos attorney. They’ll review your case and determine your likelihood of success. Many companies settle asbestos lawsuits without going to court.

Asbestos is dangerous. Home and business owners should hire trained professionals to handle it. Asbestos abatement companies will test for hazardous materials. They will take steps to prevent contaminating nearby areas of the building.

You shouldn’t attempt to handle or dispose of asbestos insulation on your own. If you suspect asbestos is in your home, don’t touch it. Instead, call a company with experience in asbestos removal.

Recommended ReadingYour web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Whitmer, M. (2025, January 13). Asbestos Insulation. Asbestos.com. Retrieved July 15, 2025, from https://www.asbestos.com/products/insulation/

Whitmer, Michelle. "Asbestos Insulation." Asbestos.com, 13 Jan 2025, https://www.asbestos.com/products/insulation/.

Whitmer, Michelle. "Asbestos Insulation." Asbestos.com. Last modified January 13, 2025. https://www.asbestos.com/products/insulation/.

An occupational scientist or another expert who specializes in occupational hazards reviewed the content on this page to ensure it meets current scientific standards and accuracy.

Sean Fitzgerald, PG, is a research geologist specializing in asbestos environmental studies.

Our fact-checking process begins with a thorough review of all sources to ensure they are high quality. Then we cross-check the facts with original medical or scientific reports published by those sources, or we validate the facts with reputable news organizations, medical and scientific experts and other health experts. Each page includes all sources for full transparency.

Please read our editorial guidelines to learn more about our content creation and review process.