Asbestos vs. Cellulose: What’s the Difference?

Awareness & ResearchWritten by Travis Rodgers | Edited By Amy Edel

When encountering home insulation during DIY projects, it’s important to know what you could be exposed to in the process. Asbestos insulation and cellulose insulation are sometimes mistaken for each other, but have different risk profiles. Knowing how to identify, remediate and replace asbestos insulation versus cellulose insulation will help homeowners avoid potential dangers.

Asbestos insulation was commonly used in homes built between the 1940s and 1970s because of its effective insulating properties and fire resistance. Its use drastically declined after its associated health risks became widely known and regulations tightened in the 1980s.

Asbestos is a known carcinogen. When disturbed, asbestos fibers can become airborne and can be inhaled. These microscopic fibers can become lodged in the body and cause cancers to develop such as mesothelioma, lung cancer and ovarian cancer.

While used since the early 20th Century, it was when asbestos use waned that the use of cellulose insulation became particularly popular. Its use also increased during the 1970s for its cost-effectiveness and environmental benefits as part of the energy conservation movement.

Cellulose insulation is primarily made from recycled paper. Cellulose itself is generally considered safe. A National Toxicology Program report, for example, indicated that cellulose particles are not likely to be inhaled. The fire retardants used to treat cellulose insulation, however, may pose health risks.

Boric acid and borax are two chemicals commonly used to reduce flammability. The Florida Department of Agriculture notes studies found boric acid is “moderately toxic” to humans when consumed in large quantities. When inhaled, exposed to skin or consumed, boron could cause serious health consequences.

It’s important to know current guidelines for dealing with fire retardant-treated cellulose or asbestos in your home. Knowing the difference between these two materials is a key place to start.

What Is Asbestos and Why Was Asbestos Insulation Used?

Asbestos is a naturally occurring mineral that was once widely incorporated into a variety of products like insulation for its resistance to heat, fire and electrical or chemical changes. This resistance made it ideal for protecting homes against temperature fluctuations and potential fire hazards.

Different types of asbestos were used in industrial and home insulation. Some were used to create asbestos insulating cement, asbestos block insulation, loose-fill asbestos insulation, spray-on asbestos insulation and preformed or loose applied asbestos insulation.

Types of Asbestos Found in Insulation

- Amosite: Also known as brown asbestos, it was frequently used in cement sheets and pipe insulation.

- Chrysotile: The most common form of asbestos, chrysotile or white asbestos can be found in roofs, ceilings, walls and floors.

- Tremolite: Tremolite wasn’t deliberately added, but vermiculite, another mineral, was often used in insulation. Vermiculite can become contaminated with tremolite asbestos.

As The Mesothelioma Center’s asbestos expert Michelle Whitmer recently told The Family Handyman in an interview, “The types of insulation in homes most likely to contain asbestos include loose-fill vermiculite insulation and wrap insulation commonly found around pipes and A/C units. Some homes may have spray-on or block insulation containing asbestos, but these materials were most common in commercial buildings.”

The ability to use asbestos for insulation in various forms – from loose-fill insulation to rigid boards – made it a desirable product for builders and homeowners. In the industrial sector, asbestos was also widely used for insulating pipes, sealing gaskets and creating other vehicle parts such as brakes. Construction workers, plumbers and mechanics are at high risk of occupational asbestos exposure.

What is Cellulose and Why Is Cellulose Insulation Used?

Cellulose insulation is made from recycled paper products such as newspapers and cardboard and is treated with fire-retardant chemicals like borax, boric acid, sodium borate and ammonium sulfate. These chemicals may have negative effects if ingested, but cellulose insulation is generally considered safe.

It’s viewed as a sustainable option and more environmentally friendly alternative to synthetic insulation products. Cellulose insulation can improve a home’s energy efficiency and offers an additional benefit of noise dampening.

Types of Cellulose Insulation

- Dense-packed cellulose: Used for closed walls and new construction projects, it offers a higher density that prevents settling and enhances soundproofing.

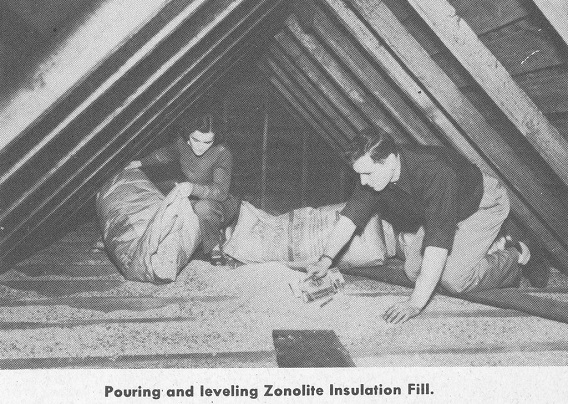

- Loose-fill cellulose: Ideal for attics and wall cavities, easily conforming to spaces without disturbing structures or finishes.

- Wet-spray cellulose: Contains a moisture additive that helps it adhere to open wall cavities, providing excellent coverage and insulation integrity.

Unlike toxic asbestos, cellulose insulation isn’t highly regulated. Disposal of cellulose insulation can vary in different localities. In some states limited amounts of cellulose insulation can be put in with household garbage, while larger amounts must be disposed of at the landfill. Check with your local refuse authorities for disposal information.

How to Tell the Difference Between Asbestos and Cellulose Insulation

Determining whether your home has asbestos insulation or cellulose insulation can be challenging. Asbestos insulation might look like fluffy, loose material or could be a rigid board. Cellulose insulation typically has a more dense, fibrous look, more like packed paper or wool. But the two materials can often appear similar.

Given the risks of asbestos, hiring a professional to test the insulation to be sure if asbestos is present is recommended. An expert can safely take samples and analyze them in a lab.

What Does Asbestos Insulation Look Like?

Asbestos insulation can be many colors including white, gray or even blue and often has a shiny, fibrous texture that can be pulled apart or easily crumbled. Its appearance varies significantly depending on its form.

Asbestos-contaminated vermiculite insulation appears pebble-like. It’s usually gray-brown or silver-gold in color.

Asbestos insulation may appear as fluffy, loose material. It can resemble cotton and is often found in attics.

Spray-applied fibrous coating looks like thick paint or plaster and was applied to ceilings and walls. Stiff or rigid boards were used as soundproofing and heat barriers.

What Does Cellulose Insulation Look Like?

Cellulose insulation is generally grayish or bluish-gray and has a soft, fluffy appearance. It can appear to be similar to loose-filled asbestos but without the shiny fibers.

The product’s appearance can depend on the materials used to make it. Often recycled paper materials such as cardboard and old newspapers are used. Cellulose insulation can also include hay, straw or other plant fibers.

Loose-fill cellulose looks soft and fluffy and can be found in cavities or attics. Dense-packed cellulose is more likely to be in walls and enclosed areas. Wet-spray cellulose is applied while wet so it can adhere to open surfaces.

Asbestos Removal and Safety

When dealing with asbestos, taking proper safety measures is essential. Removing asbestos is best left to professionals.

Certified professionals with an asbestos abatement company can safely remove asbestos insulation. Your asbestos abatement professional will know local regulations and how to dispose of asbestos properly. Professionals will take the burden of managing disposal for you.

Role of Asbestos Abatement Professionals

- Ensure proper containment: An abatement professional will follow best practices, using appropriate containment measures to prevent the spread of asbestos fibers in your home.

- Following legal guidelines: A certified professional will adhere to local and national regulations regarding asbestos removal and disposal to prevent environmental contamination.

- Use proper equipment: Professionals will have their own personal protective equipment to minimize their risk while handling asbestos insulation.

Because toxic asbestos fibers are easily disrupted and can become airborne there’s a significant risk of inhalation during removal. Inhalation or ingestion of asbestos poses serious health risks.

Asbestos can also be found in roof shingles, siding, popcorn ceilings, drywall, cement sheets, plaster, electrical switchboard panels, plumbing fixtures, thermal boilers, fireplace insulation and vinyl floor tiles. It’s important to hire a professional to remove these products as well.