Cement Plant Workers and Asbestos

Asbestos cement plant workers mixed, formed and distributed cement products that often included asbestos. Part of their job was to stir asbestos into the cement mixture, cast it into blocks and service the machinery used in manufacturing. This work caused many cement workers to develop mesothelioma.

How Cement Workers Were Exposed to Asbestos

Asbestos cement workers were employed in cement plants and asbestos cement product manufacturing plants. This work involved direct exposure to raw asbestos and required workers to handle and transport the finished asbestos cement products.

Occupational asbestos exposure was a continuous problem in an asbestos cement product factory, but one of the most serious risks was the arrival of the raw mineral, which came in sealed bags that were opened by hand. Another dangerous source of exposure was the stacking of asbestos cement sheet products, which emitted toxic dust into the air. A dust-reducing coating was sometimes applied to the surface of these products.

Another part of the manufacturing process that released significant amounts of dust was transferring the products to the shipping department. Products were placed in bucket elevators and conveyors at certain plants, which meant that fibers could easily circulate throughout the facility.

Family members who lived with asbestos cement workers and those in similar occupations, such as construction workers, have also developed asbestos-related illnesses from secondhand asbestos exposure. Workers unknowingly carried asbestos fibers home on their clothing, shoes, skin and hair, leading to the exposure of anyone who lived in the home.

Today, American manufacturers no longer make asbestos cement products. Internationally, more than 90% of the world’s asbestos is used to make asbestos cement sheets for roofing and asbestos cement pipes for plumbing and industrial uses. No government agency is currently testing these imported materials to ensure they do not contain asbestos.

Get help finding a top attorney who can get you the compensation you deserve.

Get Help NowAsbestos Products Associated with Cement Workers

Asbestos was added to a many cement products. Although the products often were 90% cement and 10% asbestos, it was enough to make the mix dangerous. The fibers were wet-mixed into the cement before it was formed and cured to create the final product.

The final, hardened mixture could be made into blocks and flat or corrugated sheets from which cement roofing slates were formed. It could also be molded into tiles, vents, gutters or pressure pipes. The products were used as coverings for boilers, furnaces, stills and pipes. Other cement products included compounds that were marketed as a roof repair material and cement sealants for use in chimneys, skylights and shingles.

Cement plant workers may have manufactured or handled the following asbestos cement products:

- Blocks

Cement blocks and cinderblocks were both made with asbestos to make them stronger and fireproof.

- Compounds, Sealants and Adhesives

Asbestos cement was used as a patching compound and sealant in and around heat sources. It was also used as a roofing adhesive to install asbestos-containing roofing shingles and corrugated sheets.

- Concrete

Asbestos concrete pipes were used in municipal water, wastewater and stormwater systems throughout the U.S. until the mid-20th century.

- Countertops

Asbestos cement countertops were used in laboratories because asbestos is resistant to heat and chemical corrosion.

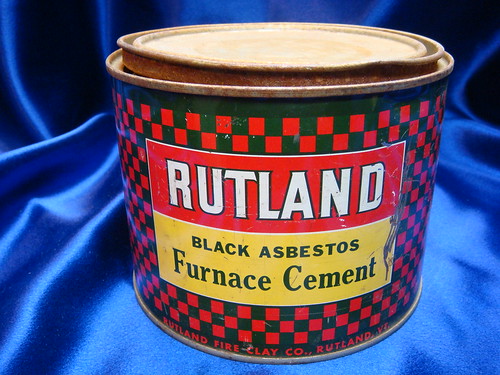

- Furnace Cement

This asbestos product was used to seal and repair furnaces.

- Gutters

Asbestos cement was formed into gutters used along roadsides and as splash gutters for home exteriors.

- Masonry

Concrete masonry served as a bonding agent that held concrete blocks and cinderblocks together, and it contained asbestos to prevent cracking in the finished product.

- Panels and Boards

Asbestos cement panels and boards were used as walls of insulation next to heat sources such as electrical boxes.

- Pipes

Asbestos cement pipes were widely used in residential homes, commercial buildings and industrial facilities. They were also used in plumbing and for various municipal and utility uses.

- Pipe Coverings

Asbestos cement pipe coverings protected pipes from extreme heat and served as a form of insulation.

- Sheets

Asbestos cement sheets were used as insulation and roofing materials. Flat sheets were used around heat sources, and corrugated sheets are still used internationally as a roofing material.

- Shingles and Siding

Asbestos cement roofing shingles and siding reduced the risk of fire in homes and other buildings.

- Stove Cement

Asbestos was added to stove cement, which served as a liner for wood-burning stoves.

- Tiles

Asbestos cement tiles could handle harsh conditions and were often used outdoors on patios and to create exterior walkways.

Manufacturers Who Employed Cement Plant Workers

Some of the asbestos industry’s biggest companies employed cement workers to manufacture asbestos cement products, including Johns Manville, Gold Bond and W.R. Grace. Many of these companies filed for bankruptcy under the weight of asbestos litigation and created asbestos trust funds to compensate future victims.

These companies included:

- Atlas Asbestos Cement Co.: This Canadian company made asbestos cement patio pots and asbestos cement tiles for patios and other outdoor uses.

- Baltimore Roofing & Asbestos Manufacturing Co.: This company made asbestos cement roofing products, siding and shingles.

- Belknap Inc.: Belknap Inc. of Louisville, Kentucky, made furnace cement containing chrysotile asbestos.

- Canadian Asbestos Ontario Limited: This Canadian company made stove and furnace cement with asbestos under the brand name Domite.

- CertainTeed Corporation: CertainTeed made several asbestos cement products, including cement pipes, blind nailing cement, cold process cement, joint treating compound, plastic cement, wet seal plastic cement and sealing cement.

- EaglePicher Industries Inc.: This company made asbestos cement products, including Super 66 Insulating Cement, One-Cote Insulating Cement, Hylo Finishing Cement and 43 Insulating Cement.

- Flintkote Company: Flintkote manufactured asbestos-containing GF-8 floor tile cement, joint cement and cement boards.

- Gold Bond: Gold Bond made asbestos-containing cement products, including cement board, Chroma-Shake cement siding, 7M-2 Thermal Insulating Cement, Mortar/Special Asbestos Cement Mix, No. 340-N Insulating Cement and Rockwool No. 340 Insulating Cement.

- Johns Manville: Johns Manville’s asbestos cement, known as Transite, became so popular that the brand name became synonymous with asbestos cement. It also made asbestos-containing cement shingles, insulating cement, corrugated transite sheets, and brand name products that included JM Shingle Tab Cement, Colorbestos roofing shingles, Permastone Asbestos-Cement Flexboard and Thermobestos Cement.

- Keasbey & Mattison: K&M made asbestos cement siding, furnace cement, Amberlerex No. 2 Asbestos Cement, Century Asbestos-Cement Shingles, Featherweight Insulating Cement, Monobestos Cement and Sheetflextos Cement.

- Mule-Hide Products: This company made asbestos plastic cement.

- National Gypsum Company: National Gypsum manufactured asbestos-containing cement sheets, siding, joint cement, topping cement and brand name products that included All-Purpose Joint Cement, Crown Coat Cement and Tri-Treatment Cement.

- Philip Carey Manufacturing Company: Philip Carey made Carey Thermo-Board concrete with asbestos.

- Supradur Manufacturing: This company produced asbestos cement roofing tiles.

- Ruberoid/GAF: This company made asbestos-containing insulation cement, Calsilite insulating cement, 7M insulating cement, cement roofing shingles, corrugated sheets and cement siding. It even made an asbestos cement ashtray.

- Rutland Fire Clay Co.: Rutland made asbestos furnace cement, roofing cement, wallboard joint cement and Ready-Mined joint cement.

- W.R. Grace: Grace made asbestos-containing Zonolite Insulating Cement and Zonolite Mono-kote Cement.

Cement Plant Workers and Mesothelioma

Scientific studies have reported increased rates of asbestos-related diseases among asbestos cement workers in the U.S. and globally. According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos.

- In 2020, a study published in Environmental Research reported an increased incidence of mesothelioma in a community where an asbestos cement factory operated. Mesothelioma was reported not only in the factory workers, but also in their family members and residents who lived in the community and a neighboring town.

- A 2019 study published in Environmental Health assessed asbestos exposure and mortality rates among workers at 21 asbestos cement factories in Italy. Significant excess deaths caused by asbestos-related diseases were reported for pleural mesothelioma, peritoneal mesothelioma, lung cancer, ovarian cancer and asbestosis.

- In 2015, a Polish study analyzed rates of asbestos-related cancer among workers at five types of asbestos-product factories that operated from the 1940s to the 1990s. The highest rate of mesothelioma occurred among asbestos cement workers, at 6.54 cases per 1,000 workers.

- A 2008 study published in Human and Experimental Toxicology found that cement factory workers experienced higher levels of oxidative stress, which other research shows plays a role in the development of mesothelioma. Workers directly exposed to cement dust and particles had higher levels of oxidative stress biomarkers than workers with indirect exposure.

- In 1987, the British Journal of Industrial Medicine published a study of 6,931 employees of two asbestos cement plants in New Orleans, Louisiana, revealing an association between the number of mesothelioma risk factors they encountered and their length of employment. The longer someone worked at a plant, the more likely he or she was to develop the cancer. Another factor contributing to increased risk was the amount of time spent working in the asbestos cement pipe production area. Workers in both plants had an average of 3.8 years of employment and an average exposure concentration of 7.6 million asbestos particles per cubic foot. Among all workers, 10 cases of mesothelioma had developed up to 1984.

Mesothelioma is a form of cancer that is almost exclusively caused by exposure to asbestos. Asbestos exposure causes other cancers, including lung cancer, ovarian cancer and laryngeal cancer. It also causes another incurable and deadly disease known as asbestosis, which involves progressive scarring of lung tissue.

It you were exposed to products containing asbestos and have been diagnosed with any asbestos-related disease, it is important to find a doctor specializing in your diagnosis. Seeking treatment from a specialist at a top cancer center will get you access to innovative treatments that may help you live longer.

We have more than 50 years of combined experience helping mesothelioma patients.

Chat NowLegal Help for Cement Workers Exposed to Asbestos

Asbestos cement workers have successfully filed lawsuits against manufacturers of the products that caused them to develop diseases such as mesothelioma, other asbestos-related illnesses and cancers.

- Richard Worthley, a former employee at the Johns Manville Illinois asbestos cement plant, died of mesothelioma after working there for 24 years. A jury awarded his family $3.4 million in 2009. The judgment in his favor concluded that the asbestos supplier to the plant, Advocate Mines Limited, was negligent because it didn’t provide any warning about the dangers of working around the raw material.

- In 2005, Ralph Pierce was awarded $3.4 million after filing a lawsuit against CertainTeed Corporation claiming his diagnosis of colon cancer was caused by exposure to the company’s asbestos cement pipes.

- In 2001, a San Francisco jury awarded $2.3 million to an asbestos cement plant worker after he filed a lawsuit against Johns Manville claiming his work at its cement plant caused him to develop asbestosis. Guadalupe Laguna worked as an asbestos cement pipe inspector and a machine operator at Johns Manville’s asbestos cement plant in Stockton, California, from 1968 to 1981.

A cement workers’ lawyer who also specializes in mesothelioma and asbestos litigation has the expertise to guide you on the types of legal claims you may qualify to file. For example, you may be eligible to file a personal injury lawsuit in addition to asbestos trust fund claims. If you’ve lost a loved one, you may be eligible to file a wrongful death claim to help cover medical costs, lost wages and funeral expenses.

Recommended Reading