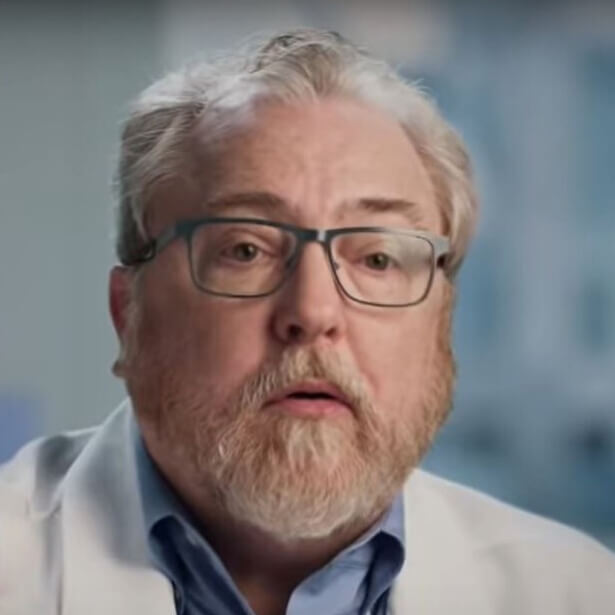

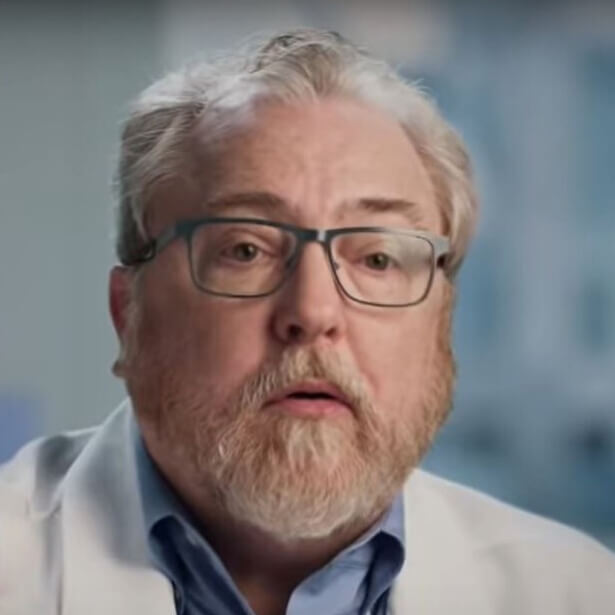

Sean Fitzgerald, PG, is a research geologist specializing in asbestos environmental studies.

Raytech Corporation Asbestos Settlement Trust compensates people exposed to Raybestos-Manhattan and Raymark brakes, clutches and friction products. Facing asbestos litigation, the company chose to file for bankruptcy and then establish a trust fund for future mesothelioma claims.

Originally, Raybestos, later renamed Raymark, filed Chapter 11 in 1989 and emerged from bankruptcy in April 2001, establishing the Raytech Corporation Asbestos Personal Injury Settlement Trust. The company was the defendant in a number of asbestos exposure lawsuits, leading to its decision to file for bankruptcy.

Raybestos-Manhattan & Raymark Industries Asbestos Trust Updates

Raytech, a spinoff of Raymark, handled Raybestos’ nonasbestos business assets starting in 1987. Asbestos liabilities from Raybestos and Raymark products stayed with the original companies, but both Raymark and Raytech eventually filed for bankruptcy.

Today, the asbestos trust fund processes claims for people exposed to asbestos from Raybestos, Raymark and related corporate entities. It pays claims to people who developed mesothelioma and other asbestos-related cancers.

Experienced mesothelioma lawyers can assist you if you were exposed to Raybestos-Manhattan and Raymark brakes or clutches to gather records from garages and plants and medical evidence to support your asbestos trust fund claim. Your attorney will submit your claim to the Raytech Corporation Asbestos Settlement Trust for you.

While you can’t sue companies with asbestos trust funds, if there are other companies that were involved in your asbestos exposure, you may be eligible to file a mesothelioma lawsuit. Your lawyer will look for any additional compensation opportunities for you, including workers’ compensation or additional trust funds.

To find a lawyer with a record of success in securing different types of financial assistance for mesothelioma survivors, speak with a Patient Advocate. Your Patient Advocate will connect you to respected and specialized attorneys. They can also arrange mesothelioma doctor appointments, resolve insurance issues, manage VA benefits claims and provide free resources and ongoing support.

Gain access to trust funds, grants and other forms of compensation for you or your loved ones.

Get Help NowIn the 1980s, CEO Craig Smith led Raymark in aggressively contesting mesothelioma claims. The company also sued some law firms representing people exposed to asbestos decades earlier.

Some notable cases include Stevens v. Raymark Industries Inc., in which the widow of a former employee received compensation after her husband died from asbestosis in 2000. Connecticut also sued Raymark and recovered costs spent on cleaning up asbestos from the company’s manufacturing plants.

A major case, Cimino v. Raymark, began as a class-action lawsuit in 1990. In 2018, a three-judge arbitration panel in Beaumont, Texas, awarded $140 million to more than 2,000 refinery and chemical workers, adding to a previous $38 million settlement.

A California jury awarded $2.1 million to a man in 2012 who developed mesothelioma after handling asbestos brake parts. He had repaired brakes as a plumber and had helped his father service trucks from a young age. He identified Raybestos as one of several companies responsible for asbestos in the brakes and brake parts he worked with.

In 1925, Raybestos added asbestos to brakes, clutches, valves, textiles and insulating materials to strengthen products and reduce the risk of fire in friction components. Arthur H. Raymond and Arthur F. Law started the A.H. Raymond Company in 1902 in Bridgeport, Connecticut, and built its reputation on the original “Raymond Brake,” expanding the brake product line throughout the 20th century.

In 1982, the company changed its name to Raymark and phased out asbestos use during the 1980s. By that time, Raybestos already faced numerous personal injury claims related to its asbestos products. The company denied knowledge of asbestos-related diseases like mesothelioma and lung cancer for decades. Sumner Simpson, who led the company for 40 years, became involved in legal proceedings while attempting to shield the company from asbestos liabilities.

From 1919 to 1989, Raymark Industries manufactured Raybestos products in Stratford, Connecticut, under various names including Raytech, Raybestos Industries and Raybestos-Manhattan. In 1985, Echlin, an automotive aftermarket supplier, acquired the Raybestos brand and formed Brake Parts Inc., which continues to produce brakes and brake parts under the Raybestos name today, primarily for automobiles.

Raybestos’ manufacturing operations in Connecticut and Pennsylvania released asbestos and other contaminants into nearby areas. Cleanup and monitoring efforts have continued for decades to reduce asbestos exposure risks and protect local communities.

Key Contamination Sites

Cleanup and monitoring projects continue in these locations to prevent future exposure. Residents and workers in these areas may still benefit from public health initiatives and ongoing environmental assessments.

Workers who handled Raybestos’ asbestos products faced significant exposure, especially those working in Raymark, Raytech or Raybestos manufacturing plants. Asbestos in brakes, clutches and industrial materials put people in multiple occupations at risk.

Higher Risk Jobs

Raybestos used asbestos in products for automobiles, trucks, trains and large industrial machinery. Its products appeared on job sites across industries, including automobile factories, chemical plants, steel mills, power plants, refineries and railways. The same asbestos materials strengthened brakes, clutches and equipment components while reducing fire risk in high-friction applications.

Raybestos produced a variety of products that contained asbestos. The material strengthened components and helped prevent fires in friction materials such as brakes and clutches.

Raybestos Products Containing Asbestos

These products were widely used in automotive, industrial and construction applications. Many of them involved high heat or friction, which is why asbestos was added to improve durability and safety.

Recommended ReadingStay up-to-date on treatment, research, clinical trials, doctors and survivors

The information on this website is proprietary and protected. It is not a substitute for professional medical advice, diagnosis or treatment. Any unauthorized or illegal use, copying or dissemination will be prosecuted. Please read our privacy policy and terms of service for more information about our website.

This website and its content may be deemed attorney advertising. Prior results do not predict a similar outcome.

The Mesothelioma Center’s claim as the most trusted resource is based on our more than 150 5-star Google and BBB reviews. Our organization also helps more than half of all mesothelioma patients annually diagnosed.

Your web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Asbestos.com. (2026, January 13). Raybestos-Manhattan & Raymark Industries Trust Fund and Lawsuits. Retrieved February 26, 2026, from https://www.asbestos.com/companies/raybestos-manhattan-raymark-industries/

"Raybestos-Manhattan & Raymark Industries Trust Fund and Lawsuits." Asbestos.com, 13 Jan 2026, https://www.asbestos.com/companies/raybestos-manhattan-raymark-industries/.

Asbestos.com. "Raybestos-Manhattan & Raymark Industries Trust Fund and Lawsuits." Last modified January 13, 2026. https://www.asbestos.com/companies/raybestos-manhattan-raymark-industries/.

An occupational scientist or another expert who specializes in occupational hazards reviewed the content on this page to ensure it meets current scientific standards and accuracy.

Sean Fitzgerald, PG, is a research geologist specializing in asbestos environmental studies.

Our fact-checking process begins with a thorough review of all sources to ensure they are high quality. Then we cross-check the facts with original medical or scientific reports published by those sources, or we validate the facts with reputable news organizations, medical and scientific experts and other health experts. Each page includes all sources for full transparency.

Please read our editorial guidelines to learn more about our content creation and review process.