Asbestos Plant Workers and Mesothelioma

Asbestos plant workers encountered the toxic mineral in every part of their job. Researchers studying one asbestos plant found the risk of dying from asbestos-related diseases increased nearly 250%. The longer the exposure, the more asbestos fibers accumulate in lung tissue.

How Were Asbestos Factory Workers Exposed to Asbestos?

All work performed in an asbestos factory endangered worker health. These plants had such high levels of asbestos circulating around the plant that every corner of the facility posed an exposure risk.

A 2020 study of eight asbestos processing plants in China found an increased incidence of mesothelioma in the population of those who lived near the plants.

In 2016, the Journal of Toxicology and Environmental Health published a study on 1,130 people who worked at an asbestos plant in Tyler, Texas, from 1954 to 1972. Researchers found that working at the plant increased a worker’s risk of dying from throat or lung cancer by 244%.

Asbestos Manufacturing Process

Asbestos plant workers were exposed at every step of the manufacturing process:

- Raw asbestos that had been milled, screened and separated into fibers arrived at the plant in bags. Workers were directly exposed by opening the bags to put the fiber bundles into an enclosed fiberizing machine that broke down the fiber bundles into smaller ones. They were exposed again when placing the bundles in bags to be transported to the area where the next stage of the process was performed.

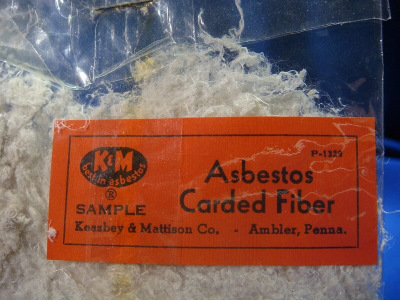

- Workers then put asbestos bundles through a machine that passed them through “teeth” so the asbestos fibers could be “carded.” This cleaned impurities from the fibers, separated them into strands and laid them parallel to each other to form a kind of thin web. This was then condensed into a single bundle known as a sliver. The carding stage created a significant amount of dust per machine, which was then removed from the work area through ducts.

- The asbestos slivers were spun into yarn in the same way as wool and cotton. The spinning machine twisted and pulled the slivers into a single yarn, which was overseen by workers operating the machine.

- The yarn was woven on looms into a variety of cloth sizes that included webbing and brake linings. Workers were exposed to asbestos while operating the looms.

- Other woven cloth was formed by workers into ropes of different sizes for the manufacture of packing material. This was known as plaiting.

Get help finding a top attorney who can get you the compensation you deserve.

Get Help NowAsbestos Products Associated with Asbestos Factory Workers

Asbestos plants produced carded asbestos fibers, asbestos yarn and asbestos rope.

Carded asbestos fibers were sold to many different industries manufacturing asbestos products that ranged from insulation to adhesives to asbestos cement pipes. Different geologic sources of asbestos became known as certain brand names of asbestos fibers. For example, Union Carbide trademarked its asbestos from a mine in California as “Calidria asbestos.” The company sold different grades of asbestos fibers, including Resin Grade 244, which was so fine workers reported that it floated in the air during production.

Asbestos yarn was sold to textile mills that manufactured a wide variety of products, including gloves for firefighters, fireproof curtains for movie theaters and heat-resistant ironing pads. Asbestos yarn was also used to make air conditioning duct connectors, pipe coverings, welder’s blankets and electrical cloth.

Asbestos rope was used as a packing material and served as a gasket material in industrial settings. It was used in pumps, compressors, seals and throughout ships for its resistance to heat and chemical corrosion.

Companies That Operated Asbestos Plants

Some asbestos mining operations owned asbestos plants to process the ore for sale. In the Eastern United States alone, 60 asbestos mines were in operation from the 1800s through 1993. Information on where the ore from these mines was processed is difficult to find.

Some asbestos plants sourced their asbestos from Canada, including Keasbey & Mattison. The company sourced its asbestos from Thetford Mines in Quebec and processed it in Ambler, Pennsylvania. Ambler now has some of the highest rates of mesothelioma and asbestos-related disease in the country.

The following companies operated asbestos plants in the United States:

- Amatex

- Bendix Corp.

- Keasbey & Mattison (Armstrong World Industries)

- Johns Manville

- King City Asbestos Corp.

- Molded Industrial Friction Corp.

- New England Asbestos Mining and Milling Company

- Raybestos-Manhattan

- Ruberoid Company (GAF Corporation)

- Union Carbide

- Vermont Asbestos Group

- W.R. Grace

Asbestos Plant Workers and Asbestos-Related Diseases

Studies show an increased incidence of asbestos-related diseases among industrial factory workers such as those in asbestos plants. According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos.

In a 2015 study of asbestos processing plant workers from Normandy, France, researchers found excess cases of esophageal cancer, liver cancer, colorectal cancer, peritoneal mesothelioma and other digestive cancers.

A 1998 study by the National Institute for Occupational Safety and Health led the agency to warn asbestos textile, friction and packing plant workers about the health risks associated with their occupations. The study found asbestos plant workers died of lung cancer at nearly double the rate of the general population.

Seventeen study participants died from mesothelioma, which is a form of cancer almost exclusively caused by asbestos exposure. Asbestosis, which is a scarring of the lung tissues, caused an additional 90 deaths in the study group when 17 deaths were expected based on the general population. The study also showed an increased incidence of death from heart disease among asbestos plant workers, which is likely because lung problems frequently lead to heart issues.

Family members of plant workers exposed to asbestos at work also developed asbestos-related diseases because workers unknowingly carried home asbestos fibers on their clothes, shoes, skin and hair. This kind of secondary exposure can cause mesothelioma and other asbestos-related diseases.

People who lived around asbestos plants also suffered higher rates of asbestos-related illness even if they or a family member never worked at the plant. This kind of exposure is known as environmental exposure because plant operations led to contamination of ambient air in the community.

Working with a doctor specializing in mesothelioma or lung cancer treatments is important for improving your chances of long-term survival. The prognosis for these conditions is poor. Most people live around one year with mesothelioma or lung cancer. Finding a specialist at a top treatment center could help you live longer with these incurable diseases.

Get help paying for treatment and other expenses by accessing trust funds, grants and other options.

Access Funds NowCompensation for Asbestos Plant Workers Exposed to Asbestos

Most asbestos plants that operated in the U.S. shut down between the 1970s and 1990s. An exception is the Coalinga mine and processing plant in California, which was operated by King City Asbestos Company and closed in 2002. Many workers who developed asbestos-related illnesses have successfully sued the companies that operated these plants and supplied asbestos fibers to various industries.

- In 2019, a New Jersey jury ordered Union Carbide to pay $2.38 million to the estate of Willis Edenfield, who died from pleural mesothelioma in 2011. Edenfield’s widow filed the wrongful death lawsuit claiming her husband developed mesothelioma from working in a factory that received 40,000 pounds of Union Carbide’s Calidria asbestos throughout a 12-year period of his employment.

- In 2014, the widow of Joe Amento settled a claim for an undisclosed amount after her husband died of pleural mesothelioma. Amento grew up in Ambler, Pennsylvania, where an infamous asbestos plant operated from the 1880s to 1987. The plant processed asbestos from Canada and branded it as “Ambler Asbestos.”

- W.R. Grace operated processing plants throughout the U.S. to process raw ore from its asbestos-contaminated vermiculite mine in Libby, Montana. The company operated a processing plant in Libby and shipped contaminated ore to 244 sites throughout the U.S., and at least 28 of these sites were processing plants. Even though these were not pure asbestos plants, workers developed asbestos-related diseases because the vermiculite ore contained approximately 20% asbestos. By 2009, the company had faced more than 950 asbestos lawsuits filed by Libby residents alone. The company filed for bankruptcy under the weight of asbestos litigation and created a trust fund to compensate future victims.

An experienced mesothelioma lawyer has the expertise to review your case and advise you on the types of claims for asbestos exposure you may qualify to file. In addition to a personal injury lawsuit or wrongful death claim, you may also qualify to file claims with asbestos trust funds.

Recommended Reading