Paper Mill Workers and Asbestos Exposure

Paper mill workers are at risk of exposure to asbestos products in equipment and in building materials. Asbestos dryer felts, gaskets and insulation were common sources of exposure in paper mills. Asbestos paper products were not made in paper mills, but they were made on traditional paper mill equipment.

How Are Paper Mill Workers Exposed to Asbestos?

Paper mill workers were exposed to asbestos products in paper mill equipment and building materials used to construct the facility. New paper mill equipment and facilities are no longer made with asbestos materials, but paper mills built before the 1990s may still contain asbestos in machinery and construction materials.

Most asbestos exposure in paper mills occurs through equipment maintenance. Because pulping, paper making and boiler operations involve high heat, asbestos was used to insulate pipes and vessels, which maintenance workers often encountered. Maintenance personnel were also at a high risk of exposure because asbestos was present in the mill machinery that they were required to inspect and repair.

Paper mill workers may have been exposed to asbestos during different stages of paper manufacturing. Talc is used as a paper additive in the bleaching and refining process of paper manufacturing, and it can be contaminated with asbestos. Mill workers also were exposed during the drying process where asbestos dryer felts, or fabrics, were used to enhance production of high-speed paper machines.

Anyone working at paper mills may have been exposed to asbestos in building materials, including industrial adhesives, pipes and ceiling and floor tiles. Asbestos was also in wall insulation, roofing shingles and siding because paper is highly flammable and the need for protection against any potential for fire was necessary.

Asbestos paper products were not manufactured in paper mills. They were produced in asbestos product manufacturing plants on Fourdrinier paper mill machines, which are used to produce conventional paper. Manufacturing workers who made asbestos paper products faced the greatest exposure risk when handling raw asbestos fibers.

Asbestos Products and Paper Mill Work

Paper mill workers were exposed to a number of asbestos products:

- Paper Mill Equipment and Materials

Paper mill equipment and materials that contained asbestos included gaskets, dryer felts, talc and sandpaper backing. To ensure that paper was produced correctly, maintenance workers opened the machinery to check that the passageways were clear and the heating elements were working properly. This could lead to the inhalation of loose fibers from the insulation and heating element holders, many of which were made of crocidolite asbestos.

During daily routine maintenance, asbestos dust was released from dryer felts in dryer machines. When the dryer felts had to be replaced, workers were exposed to asbestos particles when they hand cut and fitted the new felt into the machines. In older mills, boiler workers would remove ash from the bottom of the boilers and then reseal the boilers by applying a mixture of asbestos and cement around the boiler grate. In modern paper mills, this process is automatic.

- Building Materials

A variety of asbestos construction materials were used to build paper mills, including industrial adhesives, insulation, paneling, ceiling and floor tiles, paint, packing material, cement, countertops, roofing shingles and siding.

Asbestos insulation was the most common building material that posed an exposure threat. It was found in and around walls, doors, piping and boilers. Building maintenance workers who repaired or replaced asbestos-containing building materials were at high risk of asbestos exposure.

Learn about your diagnosis, top doctors and how to pay for treatment.

Get Your Free GuideManufacturers of Products Used in Paper Mills

Many different asbestos manufacturers supplied paper mills with asbestos products. Some of the more well-known asbestos manufacturers that supplied paper mills include:

- AstenJohnson Inc.: This company provided asbestos dryer felts to paper mills in the U.S.

- Johns Manville: JM produced many different types of asbestos building materials, including asbestos cement products, that were used to construct paper mills and other factories.

- Kaiser Aluminum: Kaiser made several kinds of asbestos building materials used in the construction of paper mills. It also made refractory cement used to insulate boilers that powered paper mills.

- Kimberly-Clark Corp.: Kimberly-Clark supplied paper mills with an asbestos sandpaper backing that was used in paper production.

- Scapa Dryer Fabrics Inc.: Scapa manufactured asbestos dryer felts that were used on dryer machines in paper mills.

Asbestos Paper Manufacturing

Even though asbestos paper products were not made in paper mills, they were produced on paper mill equipment in asbestos product manufacturing plants. This meant that workers who manufactured asbestos paper experienced similar pathways of asbestos exposure when working with or around asbestos parts on mill equipment. Maintenance workers at asbestos paper manufacturing plants were exposed to dangerous amounts of asbestos when maintaining and repairing paper mill equipment that contained asbestos parts.

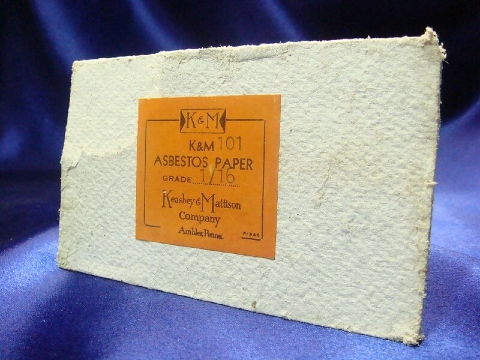

Asbestos manufacturing plant workers were exposed to the highest concentrations of asbestos when they mixed asbestos fibers with other materials to make paper products. Asbestos paper products usually contained a high asbestos fiber content ranging from 70% to 90%. They were mixed with other materials for many different applications, including pipe coverings, gaskets, insulation linings and wicks.

Asbestos paper lining was used as a form of insulation for many applications, including around air conditioning units and ductwork. Asbestos millboard was a type of stiff paper commonly mixed with clay or cement for use as a liner in stoves, toasters and other high-temperature applications. Heavy asbestos papers were used for roofing materials and shingles.

Reports of asbestos wallpaper, particularly vinyl wallpaper, are difficult to confirm, but there’s a possibility that asbestos adhesive was used to secure wallpaper onto walls.

Paper Mill Workers and Mesothelioma

Several studies have concluded that paper mill workers suffer higher rates of asbestos-related diseases, including mesothelioma. According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos.

- A 2013 Swedish study showed an increased risk of pleural mesothelioma among paper mill workers. When the exposure was further analyzed, 71% of the workers had been exposed to asbestos, the majority having worked as maintenance workers in paper mills.

- A follow-up study in 2003 of cancer rates among paper and pulp mill workers in British Columbia, Canada, reported excess cases of pleural mesothelioma. The study followed a 1997 study that found asbestos exposure in paper mills is associated with an increased risk of developing cancer.

- In 2005, an Italian study tested dust samples and machinery in a small Italian factory that manufactured paper mill dryers and found asbestos fibers present in the equipment. Three cases of pleural mesothelioma occurred among workers of the small factory that manufactured drying machines for the paper mill industry using crocidolite, amosite and chrysotile asbestos cement as insulating panels.

- A 2002 study of pleural mesothelioma and lung cancer mortality among paper industry employees found most cases occurred in maintenance workers.

- In 2000, a study of cancer incidence among male pulp workers and paper workers in Norway reported higher rates of pleural mesothelioma and lung cancer associated with departments that used asbestos.

Exposure to asbestos is known to cause four cancers: mesothelioma, lung cancer, ovarian cancer and laryngeal cancer. It also causes a pulmonary disease called asbestosis involving progressive scarring of lung tissue.

There is no cure for mesothelioma, but doctors who specialize in mesothelioma treatment can help people live longer with the condition. Innovative treatments and clinical trials are helping patients live longer, better lives with mesothelioma.

Get help finding a top attorney who can get you the compensation you deserve.

Get Help NowLegal Options for Exposed Paper Mill Workers

Paper mill workers have filed lawsuits against manufacturers using asbestos in products in addition to the companies that owned and operated paper mills.

- In February 2021, mesothelioma plaintiff Lynda Berry filed an appeal with the Second Circuit U.S. Court of Appeals, arguing her claim against Manville Forest Products, a paper mill that formerly operated as a division of Johns Manville, should not have been discharged. She said she was exposed to asbestos from the mill for 25 years after Johns Manville’s bankruptcy was complete. She claims the company did not remove asbestos from mill machinery for decades after the bankruptcy, and she was exposed through her husband, who worked at the paper mill. The outcome of the appeal remains unpublished. This is the second appeal Berry has made in her claim; she waited more than two years for an appellate judge to make a decision on her first appeal.

- Henry Barabin, a retired Crown Zellerbach Paper Mill employee suffering from mesothelioma, won a $10.2 million judgment against Scapa Dryer Fabrics Inc. and AstenJohnson Inc. in 2009. Barabin worked for Crown in Washington state from 1968 until his retirement in 2001. In November 2006, Barabin was diagnosed with pleural mesothelioma. During his employment, Barabin worked in various jobs that exposed him to the dryer felts that AstenJohnson and Scapa provided.

- In 2009, three former employees of a paper mill won more than $800,000 in a judgment against Scapa Dryer Fabrics Inc. and AstenJohnson Inc. The workers were millwrights and machine operators, and they said the companies knowingly exposed them to asbestos. Walter Patton was awarded $514,220. The two other employees were awarded $259,045 and $76,102. Evidence showed Scapa’s dryer felt contained 47.9% asbestos.

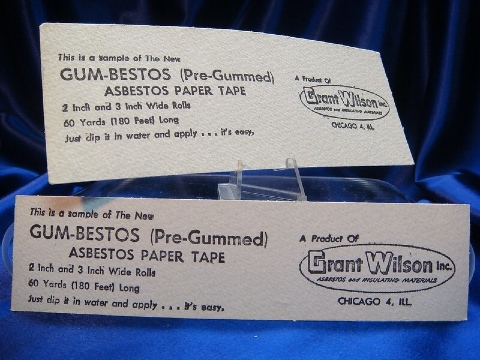

Other companies operating paper mills have been included in mesothelioma lawsuits, such as Grant Wilson and International Paper Company. Grant Wilson made many different types of asbestos products, including asbestos paper that it marketed to homeowners. The International Paper Company was one of the biggest paper producers in the U.S. In the early 1900s, it produced 60% of U.S. newspaper. The company has been named in asbestos lawsuits by former employees claiming exposure in the company’s paper mills.

If you worked in a paper mill and have developed mesothelioma, it is important to hire a mesothelioma attorney to handle your legal claims. You may be eligible to file a personal injury lawsuit and asbestos trust fund claims.

If you’ve lost a loved one to mesothelioma, you may qualify to file a wrongful death claim to access compensation for medical costs, lost wages and funeral expenses. It is best to speak with an attorney to learn more about your eligibility to file a claim.

Recommended Reading