Get answers about treatment, top doctors, and clinical trials from the nation’s most trusted mesothelioma resource.

Get Your Free GuideFactory and plant workers frequently handled asbestos during manufacturing processes, putting them at risk for severe health issues like mesothelioma. Factories, plants, and the products involved were common sources of asbestos exposure. Compensation options are available to affected workers.

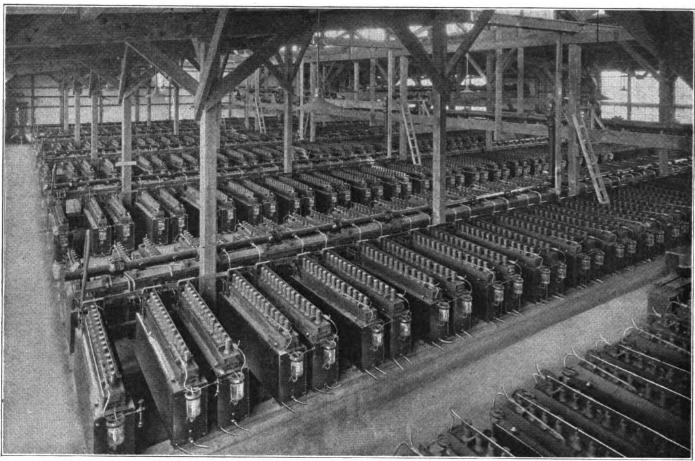

Asbestos on equipment in factories and industrial plants put workers at risk of developing mesothelioma and lung cancer. In addition to asbestos spray-ons, lagging and insulation on the surface of equipment, asbestos was sometimes incorporated into equipment in components like wiring, clutches, electrical panels and seals. Factory workers also encountered asbestos in building materials in these facilities.

Asbestos is resistant to heat and chemical corrosion, which is why these facilities used it. Airborne asbestos fibers could be released when maintaining equipment, directly exposing workers and anyone working nearby. the equipment. Heat panels, flooring, ceiling tiles, HVAC equipment, electrical wiring and pipes also had asbestos.

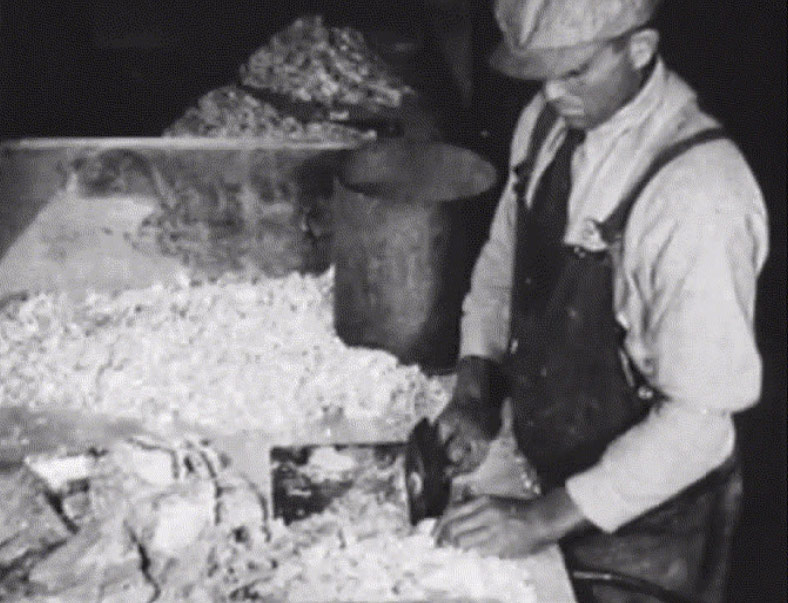

Workers at industrial plants that produced asbestos products faced significant risks. They directly handled asbestos fibers when making these products. Chemical plant workers wore clothing that had asbestos fibers woven into them and used asbestos equipment. While factory workers are at a lower risk of asbestos exposure today, legacy asbestos can still be found in older buildings, machines and equipment.

Industrial plant and factory workers used a range of asbestos products. Asbestos was considered a vital component in plant machinery and equipment. But these asbestos products often released harmful fibers. Routine handling and maintenance led to exposure.

Factories used asbestos in insulation, car parts and textiles. Before the 1980s, asbestos was common in chemicals and plastics. It served as a filler and a reinforcing agent. Companies chose asbestos for its strength and ability to resist heat. Chemical plants used it because it stopped chemical corrosion. Many workers did not know the dangers. They also did not have the proper protective gear.

Chemical plants still use asbestos diaphragms to make chlorine. The 2024 plan to ban chrysotile will end this use. The plants will phase out asbestos over 12 years.

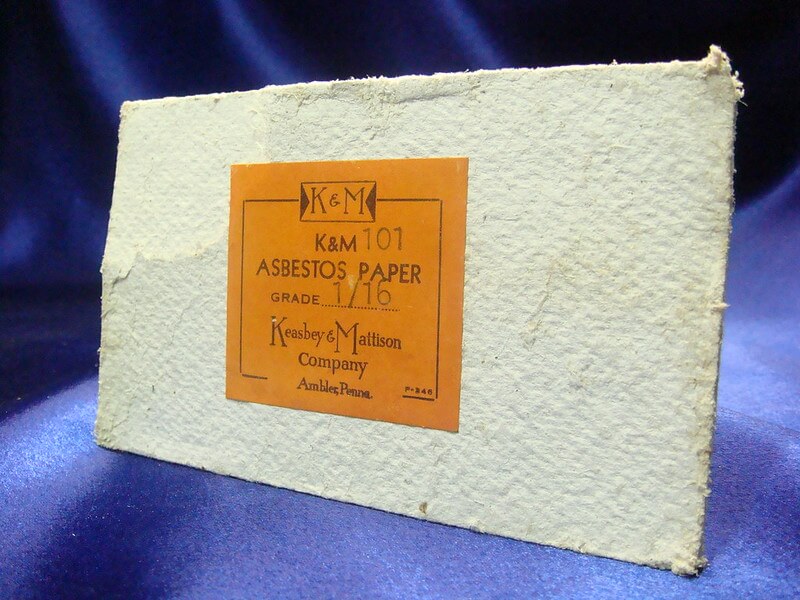

A common industrial material was asbestos paper used in wraps and packing.

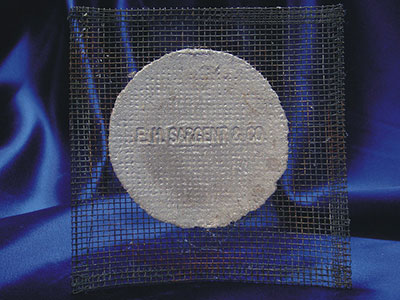

Industrial workers used asbestos textiles such as rope lagging and braided packing.

Asbestos insulation on chemical equipment stopped corrosion and fires. Incinerators, lab ovens and countertops contained asbestos. So did mixing machines, steam-jacketed kettles and reactor vessels. Radiator stop-leak products, Bunsen burner pads and gaskets also had asbestos.

Builders used asbestos to build factories and chemical plants. They used asbestos materials heavily in the 20th century through the 1980s. Insulation, pipes, flooring and wallboard contained asbestos. So did sealants, adhesives, molded flexible parts and cement block primers and elastomers.

Asbestos friction products include brake linings and clutches. Machines and vehicles at factories used these products.

Machinery parts had asbestos insulation and gaskets. Pumps, compressors and seals had asbestos for its resistance to heat and chemical corrosion. Exposure occurred during installation, maintenance or repair.

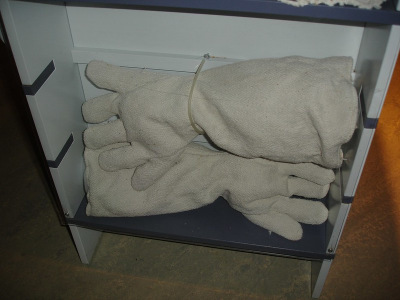

Plant workers wore protective clothing made of asbestos. This included face masks, gloves, coveralls, and aprons. They used this gear to shield themselves from heat and strong chemicals. They also used asbestos blankets to put out any fires that developed during combustion of chemicals.

Chemical plants mixed asbestos into certain materials. Plastic molding compounds are an example. This required workers to handle bags of raw asbestos fibers.

Many companies made asbestos products for use in factories and chemical plants. These companies played a big role in exposing workers to asbestos. They knew asbestos materials were dangerous, yet they still put many workers at risk. This led to serious health issues for decades.

Companies That Made Asbestos Products for Factories

Factory production employment peaked in the early 1950s. Production jobs made up about 32% of U.S. employment then. This was also when asbestos use was high. As a result, many American workers encountered asbestos. Today, production jobs make up only 5.7% of U.S. employment. The U.S. Bureau of Labor Statistics reported this in April 2025.

While the use of asbestos has declined, workers exposed in the past may face a mesothelioma diagnosis in the future. The latency period of the disease is 20 to 60 years. Occupational asbestos exposure can also cause laryngeal cancer, lung cancer and ovarian cancer.

Get answers about treatment, top doctors, and clinical trials from the nation’s most trusted mesothelioma resource.

Get Your Free GuideResearch shows former factory and industrial plant workers are at a higher risk of mesothelioma. New studies show long exposure is linked to more disease. A 2024 study in the American Journal of Industrial Medicine looked at duration and intensity of asbestos exposure among factory workers from a Tyler, Texas, asbestos plant.

Researchers at the Department of Occupational and Environmental Medicine, University of Texas at Tyler Health Science Center who authored the study concluded, “Results from this study reiterate the association between occupational asbestos exposure and mesothelioma, emphasizing the importance of concentration of respirable asbestos dust levels and duration of exposure.” Factory workers performing tasks with higher and longer asbestos exposure had more incidence of mesothelioma.

Pleural mesothelioma survivor Antonio L. worked at a corrugated cardboard factory for 35 years. He often spent hours sweeping asbestos dust that collected at the factory. Eventually, Antonio developed mesothelioma.

His son, Will, tells us, “Even though he’s sad about getting the disease, he wants us to know he did it for us. That job is what allowed us to do what we’ve done in life. He was proud of his job.”

Factory workers can file personal injury lawsuits seeking compensation. They can also file asbestos trust fund claims. Compensation can help with medical costs, lost income and other related expenses.

Workers have won asbestos lawsuits against factories and industrial and chemical plants. Examples include Dow Chemical and Hill Brothers Chemical.

Notable Verdicts and Settlements for Factory Workers

Successful cases show why having skilled legal help when seeking justice matters. Top nationwide mesothelioma firms offer the most experience. They manage claims for asbestos exposure throughout the U.S.

Recommended ReadingStay up-to-date on treatment, research, clinical trials, doctors and survivors

The information on this website is proprietary and protected. It is not a substitute for professional medical advice, diagnosis or treatment. Any unauthorized or illegal use, copying or dissemination will be prosecuted. Please read our privacy policy and terms of service for more information about our website.

This website and its content may be deemed attorney advertising. Prior results do not predict a similar outcome.

The Mesothelioma Center’s claim as the most trusted resource is based on our more than 150 5-star Google and BBB reviews. Our organization also helps more than half of all mesothelioma patients annually diagnosed.

Your web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Whitmer, M. (2026, February 12). Factory Workers and Asbestos. Asbestos.com. Retrieved February 21, 2026, from https://www.asbestos.com/occupations/factory-workers/

Whitmer, Michelle. "Factory Workers and Asbestos." Asbestos.com, 12 Feb 2026, https://www.asbestos.com/occupations/factory-workers/.

Whitmer, Michelle. "Factory Workers and Asbestos." Asbestos.com. Last modified February 12, 2026. https://www.asbestos.com/occupations/factory-workers/.

An occupational scientist or another expert who specializes in occupational hazards reviewed the content on this page to ensure it meets current scientific standards and accuracy.

Arti Shukla, Ph.D., is an internationally renowned asbestos researcher known for her achievements in identifying biomarkers that cause mesothelioma. She is the director of the Shukla Research Lab, as well as a professor of pathology at The University of Vermont Larner College of Medicine.

Our fact-checking process begins with a thorough review of all sources to ensure they are high quality. Then we cross-check the facts with original medical or scientific reports published by those sources, or we validate the facts with reputable news organizations, medical and scientific experts and other health experts. Each page includes all sources for full transparency.

Please read our editorial guidelines to learn more about our content creation and review process.