Factory Workers and Asbestos

Factory workers and machine operators have a higher risk of developing mesothelioma, lung cancer and other asbestos-related diseases because they were exposed to asbestos-containing equipment and building materials in factories. Factory workers who manufactured asbestos products are at the highest risk of developing asbestos-related diseases.

Written by Michelle Whitmer • Edited By Walter Pacheco • Scientifically Reviewed By Arti Shukla, Ph.D.

Asbestos.com is the nation’s most trusted mesothelioma resource

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

About The Mesothelioma Center at Asbestos.com

- Assisting mesothelioma patients and their loved ones since 2006.

- Helps more than 50% of mesothelioma patients diagnosed annually in the U.S.

- A+ rating from the Better Business Bureau.

- 5-star reviewed mesothelioma and support organization.

Testimonials

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

How to Cite Asbestos.com’s Article

APA

Whitmer, M. (2024, March 25). Factory Workers and Asbestos. Asbestos.com. Retrieved April 25, 2024, from https://www.asbestos.com/occupations/factory-workers/

MLA

Whitmer, Michelle. "Factory Workers and Asbestos." Asbestos.com, 25 Mar 2024, https://www.asbestos.com/occupations/factory-workers/.

Chicago

Whitmer, Michelle. "Factory Workers and Asbestos." Asbestos.com. Last modified March 25, 2024. https://www.asbestos.com/occupations/factory-workers/.

How Factory Workers Are Exposed to Asbestos

Many production machines in factories contained asbestos parts and insulation, and workers faced exposure hazards when the products became friable. Factories were also constructed with asbestos insulation, tiles, bricks and drywall that put workers at risk of exposure. The worst exposure happened at asbestos product factories where workers transported, handled and mixed raw asbestos fibers to manufacture asbestos products.

Factory and production workers often repeat the same set of tasks in their job, whether assembling products or maintaining factory equipment, which contributed to repeated asbestos exposure. Regardless of their position, most factory workers faced some form of occupational asbestos exposure, whether working as a manager, office staff or in a warehouse.

While most factory workers faced exposure hazards, machine maintenance crews had some of the highest risks. These workers repaired asbestos parts that were already disintegrating, placing them in direct contact with friable asbestos. Grinding machine operators, drill press operators, equipment mechanics and assembly workers also worked closely with this equipment.

Machinery operators faced these risks as well. They came into contact with asbestos as soon as the machines released it into the air. Drill press operators were especially prone to exposure. When they created holes in asbestos-contaminated products, the fibers quickly flew up into the air. When factory workers used grinding machines, small fragments often broke off when the wheel made contact with another surface. This allowed the asbestos in the wheel to become friable. Similarly, when workers drilled through or cut asbestos components, the loose fibers entered their breathing space. Workers who were stationed near transportation belts also faced high exposure risks.

Family members of factory workers have become ill because workers unknowingly brought home asbestos fibers on their clothing, skin and hair. Secondary asbestos exposure can cause mesothelioma and other asbestos-related cancers and conditions.

Asbestos Products Associated with Machinists and Factory Workers

Factory workers were at risk of exposure to many different types of asbestos products used as construction materials and machine equipment parts. While asbestos is no longer used in the construction of new factories or in the maintenance of machinery, old factories and machinery may still contain asbestos materials that could expose workers today.

Factory workers were at risk of exposure to the following asbestos products:

Asbestos Machinery Parts: Asbestos insulation, gaskets, valves and valve packing, bearings, pumps, electrical equipment, conveyer belts and other pieces of machinery equipment contained asbestos to protect against heat, fire and chemical erosion. Lathes, for example, contained asbestos insulation around their friction components. As daily use wore down the insulation, the loose asbestos became a potential exposure hazard. Workers repaired burn holes in conveyor belts with asbestos ply inserts and replaced asbestos bearings on high-friction production machinery.

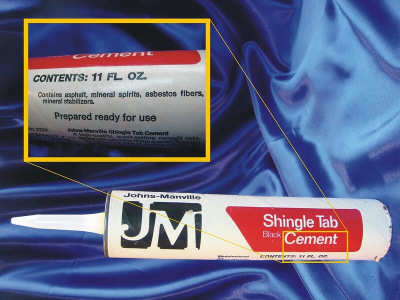

Construction Materials: Asbestos tiles, bricks, drywall, wallboard and insulation were used throughout factories to prevent fires. Asbestos cement, putties, joint compounds, mastics and adhesives were also regularly used in factories. Asbestos insulation was by far the most commonly used asbestos material in factories. It was found in walls, ceilings, flooring and around pipes and boilers as a form of wrap insulation.

Raw Asbestos Fibers: Workers in asbestos product factories were exposed to raw asbestos fibers, whether directly or indirectly. Some workers transported bags of asbestos, directly handled raw fibers and mixed them with other materials to make asbestos products. This work caused visible and microscopic asbestos fibers to circulate throughout factories, causing indirect exposure among other workers.

Manufacturers That Made Products Factory Workers Use

Factory workers were exposed to asbestos products from dozens of different manufacturers because so many types of asbestos products were used in factories.

The most notable manufacturers include:

- Raybestos: This company made asbestos brakes, clutches and valves that were used on factory machinery.

- B.F. Goodrich: In addition to manufacturing tires and rubber products, B.F. Goodrich made asbestos-containing conveying systems, transportation belts and belt drives used in production factories.

- Flexitallic Gasket Company: Flexitallic manufactured asbestos-containing spiral-wound gaskets used in factories and industrial settings.

- Johns Manville: Johns Manville made many different construction materials with asbestos that were used to construct factories, including asbestos cement.

- Honeywell: Honeywell made different types of asbestos brake pads and linings that were used in factory machinery.

- Pneumo Abex: This company made asbestos-containing brakes, hydraulic systems and fluid power parts that were used in factory machinery.

Mesothelioma and Factory Workers

Scientific studies have shown factory workers develop asbestos-related diseases at higher rates than the general population. According to a 2022 report by the European Commission, over 70,000 workers died in 2019 from past exposure to asbestos.

- In 2015, a British Medical Journal study reported asbestos-related deaths in Belgian workers from 2001-2009. The data showed that metal product factory workers were 87% more likely to die of mesothelioma than the general population.

- One notable 2010 study followed the workers at a Raybestos Manhattan factory in Connecticut. These workers manufactured several different friction products with chrysotile and anthophyllite asbestos. Researchers noted seven mesothelioma cases, all of which were traced to occupational exposures. This study debunked a previous study’s claim that there were no asbestos-related deaths among the factory’s workers.

- A 1989 study found that workers in an auto parts factory had significantly higher lung cancer and laryngeal cancer mortality rates than the general population. These workers often used chrysotile asbestos and asbestos-contaminated abrasives to create drum brakes and linings. Most of the workers were responsible for drilling, grinding and riveting the products. A 1975 sampling survey found up to two asbestos fibers per milliliter of air in the factory. However, the hygienists added that the concentration may have been much higher before that time.

- One other research project published in 1980 found an increased incidence of mesothelioma and bronchial carcinoma cases in workers at a wartime gas mask factory. These workers handled crocidolite asbestos on a regular basis, but often for a period of less than five months. The researchers did not note an excess of any other malignancies.

One of the most large-scale occupational asbestos exposures occurred near the J.W. Roberts Ltd. factory in Leeds, England. The factory workers manufactured Limpet, a form of spray-on asbestos insulation, until the factory closed in 1959. However, employees were not the only ones to come into contact with the fibers. The factory’s ventilation systems deposited thick layers of asbestos dust into the neighborhood, where it coated sidewalks, homes and yards. Since then, health professionals have seen abnormally high levels of illness in former workers as well as community residents.

Exposure to asbestos is known to cause mesothelioma, lung cancer, ovarian cancer, laryngeal cancer and asbestosis. Mesothelioma is a form of cancer almost exclusively caused by asbestos exposure and there is no cure for the disease. If you are diagnosed with mesothelioma, it is important to work with a mesothelioma doctor to access innovative treatments and clinical trials.

If you are a former factory worker and develop concerning respiratory or digestive problems, tell your doctor about your asbestos exposure history and request cancer screenings. Catching asbestos-related diseases early in their development can improve treatment outcomes.

Compensation for Factory Workers Exposed to Asbestos

Factory workers have successfully sued manufacturers of the asbestos products that caused them to develop mesothelioma and other illnesses. Compensation received through legal claims have helped workers afford medical treatments and make up for lost wages.

- In 2010, a former factory worker earned New Jersey’s largest asbestos verdict. The man, Mark Buttitta, was exposed to asbestos as a parts picker at a General Motors factory distribution warehouse. (He also experienced secondhand exposure from his father’s clothes.) These exposures led him to develop mesothelioma, which he died from within a year. A few years after his death, the New Jersey jury awarded his family $30.3 million.

- Another unique case involved Jayne Menssen, a secretary for a Bloomington, Illinois, rubber factory. She worked for the factory throughout the 1960s, when asbestos products were widely used in production, but never handled the products herself. However, the factory was so heavily contaminated with asbestos from Pneumo Abex and Honeywell International materials that Menssen still developed mesothelioma. After a four-week trial in 2010, Menssen’s jury decided on a $17.8 million verdict.

- In 2008, former assembly line worker and product packager Linda Lyon filed an asbestos lawsuit with a Wisconsin circuit court. She had been living with mesothelioma for six years, but the diagnosis ended her 28-year career. She requested $100,000 to cover medical expenses and lost wages. However, the courts have not made the final verdict public.

- Another mesothelioma patient filed an asbestos lawsuit to help balance out the costs of his treatment. The former factory worker, James Crawford, took his case to court after paying several thousand dollars for a surgery. He listed 32 different product manufacturers that contributed to his exposure, and an Illinois jury awarded him a total verdict of $16 million in 2001.

Factory workers who develop mesothelioma from occupational asbestos exposure may file a personal injury lawsuit against the manufacturers responsible for their asbestos exposure. They may also qualify to file multiple asbestos trust fund claims depending on their exposure history. It’s important to work with a mesothelioma lawyer with experience in asbestos litigation to ensure your case is handled properly to maximize compensation.

If you’ve lost a loved one to mesothelioma, you have the right to file a wrongful death lawsuit to seek compensation for medical expenses, lost wages and funeral costs.