Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

Because asbestos is nonflammable, noncombustible and has an extremely high melting point, it became a popular choice for fireproofing building materials and textiles. As a result, asbestos has been found in products for firefighting, construction and home goods.

Asbestos works well as a fire-resistant material because of its chemical properties. It is nonflammable and noncombustible and has a melting point of around 1,600 degrees Fahrenheit. Asbestos consists of lightweight fibers that are stronger than cotton, rayon or nylon. The fibers are also flexible enough to be woven with other fibers, mixed and sprayed with cement or mixed with other materials.

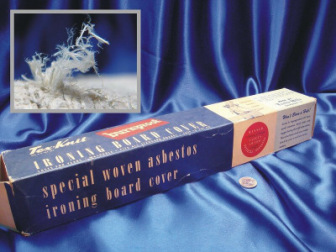

Asbestos was an inexpensive additive used to create a range of affordable, fire-resistant products, including building materials such as roofing shingles, wallboard, concrete, insulation and coatings. It was woven into textiles to make fire-resistant fabrics and cloth used by firefighters and industrial workers, and it was added into consumer goods such as ironing board covers and appliances.

While American companies no longer make these materials with asbestos, only one asbestos fireproofing product is banned in the U.S.: spray-on asbestos fireproofing. It was banned in 1970 through the passage of the Clean Air Act. Imported roofing and flooring materials from countries such as China and India may contain asbestos.

In addition to encountering asbestos products in burning buildings, firefighters experienced direct exposure to asbestos through the clothes they wore and the gear they used to fight fires.

As a result, firefighters are among the most at-risk occupations for developing mesothelioma and other asbestos-related diseases.

Asbestos was added to the following firefighting gear:

Consumers and homeowners should know that asbestos was used in consumer goods and home building materials to prevent fires.

Asbestos was also used in many different tools and machinery that operated at hot temperatures in commercial or industrial settings.

Asbestos has been found in the following consumer goods and building materials:

Spray-on asbestos fireproofing was used in the construction of the World Trade Center in New York City. As a result, asbestos dust was released into the air following the collapse of the twin towers on Sept. 11, 2001.

According to a 2016 health study conducted by the World Trade Center Health Registry, following the collapse more than 352 people have developed asbestosis, an additional 444 people have developed pulmonary fibrosis and 16% have been diagnosed with cancer. At least two people exposed to 9/11 dust have died from mesothelioma.

Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

People exposed to asbestos in fireproofing products are at risk for developing asbestos-related disease, such as asbestosis, lung cancer and mesothelioma. Different fireproofing products contain different levels of asbestos, and greater exposure leads to a greater risk.

For example, ceiling tiles contain on average 10% asbestos, while insulating boards could contain up to 40% asbestos. Textiles developed for fireproofing purposes could be made of as much as 100% asbestos.

Because of the prevalence of asbestos fireproofing products, many different occupations were exposed to asbestos. Construction workers and firefighters are particularly at risk of exposure to high concentrations of asbestos. When buildings are renovated, demolished or affected by fire, products that contain asbestos are easily damaged.

Spray-on asbestos fireproofing was a particularly dangerous material. When it was first applied, it was a wet, foam-like material. As it dried out, it became friable. Friable means that the material crumbles easily. As spray-on asbestos fireproofing ages it becomes even more friable, often to the point where even the slightest disturbance will cause dangerous asbestos exposure. Brands of spray-on asbestos fireproofing include Monokote, Limpet, Cafco and Spraycraft.

Since the 1970s, U.S. courts have required companies that manufactured asbestos fireproofing products to pay compensation for the medical costs, lost wages and pain and suffering mesothelioma and other asbestos-related diseases caused. These companies were held liable for the diseases their products cause because they were aware that asbestos leads to adverse health effects.

When filing a mesothelioma claim, the right legal representation is everything. We’ll connect you to a top lawyer who will help you secure financial compensation.

Find an AttorneyAbatement of asbestos fireproofing materials should always be done by licensed professionals. Many asbestos fireproofing materials are considered Class I by the Occupational Safety and Health Administration, which is the most dangerous class of asbestos-containing products.

Examples of Class I asbestos materials include:

It is also important to hire a licensed professional if you suspect your home contains asbestos in building materials. Removing these materials could generate asbestos dust and result in unnecessary exposure among family members.

If you find old consumer goods that may contain asbestos, call your local department of environmental quality to inquire about proper disposal in your area. Certain landfills are equipped to take asbestos waste, and you need to follow proper bagging and disposal procedures. If the product appears damaged, hire a licensed professional to handle and dispose of it properly.

The use of asbestos in fireproof materials and products continued to increase until the early 1970s, when several studies linking the mineral to lung cancer and mesothelioma were published. These studies led the U.S. Environmental Protection Agency and the Occupational Safety and Health Administration to restrict the use of asbestos. Federal legislation also prevented the production of spray-on asbestos fireproofing.

Starting in the 1950s, lightweight insulation materials such as spray-on fireproofing were used in tall buildings. These ultra-lightweight asbestos materials were applied to steel and other core building structures to prevent them from buckling during a fire. One of the first high-rises to contain spray-on asbestos fireproofing was the Chase Manhattan Bank in New York City, built in 1958. The use of asbestos-containing insulation in high-rise buildings was ubiquitous by 1970. W.R. Grace, Isolatek International, United States Gypsum, J.W. Roberts Limited and U.S. Mineral were among the manufacturers of asbestos fireproofing spray.

Two men, Henry Ward and Ludwig Hatschek, are credited with implementing the earliest mass production of fireproof asbestos construction materials. Ward, a building contractor, made fireproof paint and fire-resistant tar paper for roofing in the 1860s. In 1900, Hatschek, an engineer, made the Hatschek machine, which was the first machine that could cheaply and efficiently produce asbestos roof panels.

During the 1500s and 1600s, scientists such as George Agricola, the father of modern mineralogy, were intrigued by asbestos and extensively researched and wrote about the mineral. This scientific research eventually led to inventors using asbestos to create new and better products. In the United States, Benjamin Franklin made one of these first inventions, leveraging the fire-resistant characteristics of asbestos – a fireproof purse – which now lives in the Natural History Museum in London.

Recommended ReadingStay up-to-date on treatment, research, clinical trials, doctors and survivors

The information on this website is proprietary and protected. It is not a substitute for professional medical advice, diagnosis or treatment. Any unauthorized or illegal use, copying or dissemination will be prosecuted. Please read our privacy policy and terms of service for more information about our website.

This website and its content may be deemed attorney advertising. Prior results do not predict a similar outcome.

The Mesothelioma Center’s claim as the most trusted resource is based on our more than 150 5-star Google and BBB reviews. Our organization also helps more than half of all mesothelioma patients annually diagnosed.

Your web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Whitmer, M. (2026, February 12). Asbestos Fireproofing & Fire Prevention Materials. Asbestos.com. Retrieved February 27, 2026, from https://www.asbestos.com/products/fireproofing-fire-prevention-materials/

Whitmer, Michelle. "Asbestos Fireproofing & Fire Prevention Materials." Asbestos.com, 12 Feb 2026, https://www.asbestos.com/products/fireproofing-fire-prevention-materials/.

Whitmer, Michelle. "Asbestos Fireproofing & Fire Prevention Materials." Asbestos.com. Last modified February 12, 2026. https://www.asbestos.com/products/fireproofing-fire-prevention-materials/.

An occupational scientist or another expert who specializes in occupational hazards reviewed the content on this page to ensure it meets current scientific standards and accuracy.

Sean Fitzgerald, PG, is a research geologist specializing in asbestos environmental studies.

Our fact-checking process begins with a thorough review of all sources to ensure they are high quality. Then we cross-check the facts with original medical or scientific reports published by those sources, or we validate the facts with reputable news organizations, medical and scientific experts and other health experts. Each page includes all sources for full transparency.

Please read our editorial guidelines to learn more about our content creation and review process.