Navy veteran Bob Niemiec entered the Navy in 1965 at the age of 20. His first assignment out of boot camp was to scrape paint off of the landing ship U.S.S. Hermitage. It turns out the paint he was scraping contained asbestos. Niemiec said he didn’t feel the effects of the asbestos exposure until many years later, about 30 years after his stint in the Navy.

Asbestos Exposure on Navy Ships

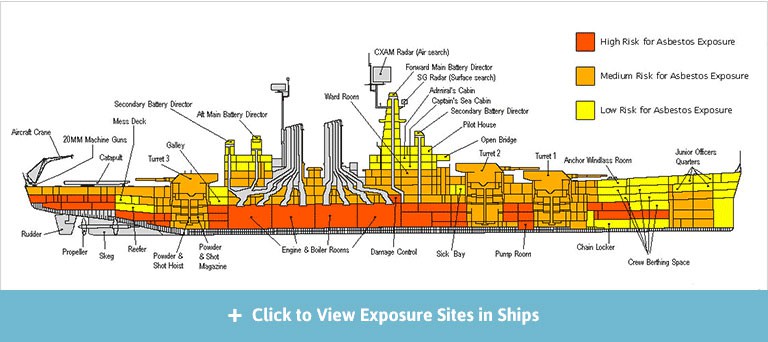

More than 300 asbestos products were used on U.S. Navy ships from the 1930s to early 1980s. This widespread use exposed Navy veterans to asbestos, putting them at high risk for mesothelioma and other asbestos-related diseases.

Asbestos on Navy Ships

Many U.S. Navy ships built before 1980 contained asbestos. Sailors exposed to asbestos on these ships often developed cancers like mesothelioma and other serious conditions related to asbestos.

More than 300 materials that contained asbestos were once used in Navy ships. The toxic mineral could be found in products like decking, gaskets and paint. And asbestos was used throughout ships from boiler and engine rooms to mess halls and sleeping quarters.

Most naval personnel were not required to wear protective air masks or wet down asbestos-containing materials before removal to help prevent fibers from going airborne. A lack of enforcement of safety measures contributed significantly to the risk of asbestos exposure to those on board.

Navy veterans are at a high risk of developing mesothelioma because of the amount of asbestos the United States military used. Veterans were exposed to asbestos during the course of doing their jobs aboard ship in the Navy or Coast Guard.

Navy Occupations With High Asbestos Exposure

Navy records from ship databases, letters, memos, repair logs, war diaries and historical documents show many Navy jobs involved a higher risk of asbestos exposure. Ships used many types of equipment that contained asbestos. Maintaining or repairing this equipment released asbestos dust that Navy personnel could easily inhale.

Higher Risk Navy Jobs

- Boatswain’s mate

- Damage controlman

- Electrician’s mate

- Fire control technician

- Gunner’s mate

- Hull maintenance technician

- Machinery repairman

- Machinist’s mate

- Metalsmith

- Pipefitter

- Water tender

- Welder

A quantitative assessment published in the International Journal of Radiation Biology studied 114,000 Navy veterans. The research showed Navy personnel who worked as machinist’s mates, boiler technicians, pipe fitters, fire control technicians and water tenders had the highest mesothelioma mortality rates of those in the study.

Items on Navy Ships Containing Asbestos

Equipment on Navy ships had asbestos either packed inside it, sprayed on or manufactured into the materials. The main sources of exposure were boilers, pipes and pumps.

Boilers were coated with external insulation containing about 15% asbestos, contained loose asbestos packing and had asbestos gaskets. Insulation coated a sprawling network of pipes with a felt layer that contained 5% to 50% asbestos. Damaged coating required service members to mix dry asbestos with water to make new insulation coating.

Navy Equipment With Asbestos

- Adhesives

- Aggregate mixtures

- Bedding compounds

- Block insulation

- Boilers

- Cables

- Capacitors

- Deck-covering materials

- Gaskets

- Grinders

- Hydraulic assemblies

- Insulating materials

- Paneling

- Pipe insulation

- Pumps

- Packing materials

- Thermal materials

- Tubes

- Valves

Machinist’s mates risked asbestos exposure when replacing worn asbestos gaskets inside mechanical pumps that powered heating, cooling and bilge systems. They used scrapers and wire brushes to remove stubborn gaskets, releasing toxic asbestos fibers.

Pipefitters, boiler operators and other Navy crew members were also exposed doing their jobs. Working with ship valves that contained asbestos gaskets, had asbestos insulation coatings and were filled with asbestos packing put the crew at risk.

Where was asbestos in your Navy ship?

- Years Active:

- Hull Number:

- Ship Type:

- Ship Builder:

Asbestos on Navy Ships Today

Fewer products with asbestos are used on Navy ships and shipyards today, but it’s still allowed if there are no better options. The Navy doesn’t share when it approves the use of asbestos now, making it hard to know how often it happens.

The Navy has worked to remove existing asbestos from its ships. As asbestos ages, it gets more brittle and more challenging to remove. The Asbestos Medical Surveillance Program, the medical component of the Navy Asbestos Program, says, “All Navy asbestos workers, both Active Duty and civilian, are enrolled in the AMSP, making the AMSP the largest program of its kind in the world.”

Even with the Navy removing many asbestos products, some harmful material is still on many ships. As of March 28, 2025, the National Defense Reserve Fleet reports it has 100 “military-useful former commercial ships” as well as 48 vessels in The Ready Reserve Force. The Navy reportedly currently has approximately 296 deployable vessels.

Navy Veterans and Mesothelioma

Asbestos exposure has compromised the health of many veterans. The U.S. Department of Health and Human Services, the U.S. Environmental Protection Agency and the International Agency for Research on Cancer all say asbestos can cause cancer.

In the EPA’s statement about its 2024 chrysotile asbestos ban, the agency stated, “Exposure to asbestos is known to cause lung cancer, mesothelioma, ovarian cancer and laryngeal cancer, and it is linked to more than 40,000 deaths in the U.S. each year.” When workers breathe in asbestos fibers without protection, these fibers can get stuck in the tissue around the lungs.

Over several decades, asbestos fibers stuck in tissue cause irritation. This can lead to cellular and genetic damage. Tumors can grow and malignant mesothelioma cancer can develop.

Asbestos Exposure Risks by Ship Type

Asbestos contamination wasn’t limited to one specific class of vessel. Asbestos was used in everything from destroyers to aircraft carriers. Asbestos’ fire-resistant and insulating properties made it a prized material before its health risks were more well-known.

Exposure occurred on deck when service members maintained or repaired asbestos-containing products such as matting and tiles. The most concentrated exposure happened below deck in places like engine and boiler rooms because of the lack of ventilation.

Machinist’s mates, for example, risked asbestos exposure when replacing worn asbestos gaskets in pumps. These pumps powered the heating, cooling and bilge systems. Many sailors unknowingly inhaled asbestos fibers when stationed in engine rooms, working with pipes and insulation or simply living aboard these vessels.

Aircraft Carriers

Aircraft carriers are the largest Navy ships, functioning as floating airbases. Asbestos was commonly used to prevent fires in engine and boiler rooms and around pipes. Even sleeping quarters and mess halls contained asbestos in ceiling tiles and floors.

Sailors repairing these ships faced significant risk, often working without protective gear. Disturbing asbestos during repairs released harmful fibers, exposing many sailors to asbestos.

Destroyers

Destroyers were built for speed and agility, often accompanying larger ships and fighting in combat. They used asbestos insulation in many parts like walls, boilers, turbines and pumps. The constant movement and harsh sea conditions caused the asbestos to break down, releasing harmful fibers into the air.

Crew members in engine and boiler rooms worked directly with asbestos-covered equipment. Those doing repairs also faced dangers when changing worn insulation. They experienced prolonged exposure in tight spaces. Many veterans who served on destroyers were later diagnosed with asbestos-related illnesses.

Submarines

Submarines had small, poorly ventilated spaces. And asbestos was used for insulation, soundproofing and fireproofing around pipes, electrical systems and engines. Submariners were at a higher risk of breathing in asbestos fibers since they lived and worked close to these materials.

Any maintenance on asbestos-containing materials raised the risk. Routine tasks like changing gaskets or working in control rooms could kick up asbestos dust. With the limited airflow in submarines, these fibers could stay in the air for a long time, leading to constant exposure.

Minesweepers

Minesweepers played an important role in naval warfare, removing mines from waterways. They had asbestos in their engine rooms, pipes and electrical systems to fireproof and insulate key parts.

Sailors on minesweepers risked exposure to asbestos during their daily tasks. Over time, the asbestos materials wore down, and repairs often involved cutting or sanding insulation. Crew members, often without proper protective gear, inhaled asbestos fibers, causing disease.

Cruisers

Cruisers were adaptable warships used in attacks and defenses. These armed ships used asbestos to shield machinery, weapon storage and living spaces. Areas like engine rooms and bulkheads had asbestos insulation to help prevent fires.

The heat from the ship’s power systems caused the asbestos materials to break down over time, creating dust in the air. Regular maintenance, like fixing pipes and changing insulation, put crew members at risk of breathing in this toxic dust. Many sailors later developed diseases from long-term asbestos exposure.

Auxiliary Vessels

Auxiliary vessels, such as supply ships, transport ships and hospital ships, supported the Navy. They carried cargo, fuel and medical supplies. They also helped other ships. These ships used asbestos to insulate pipes, walls and engines.

Unlike combat ships, auxiliary ships had military personnel and civilian workers on board, all at risk of asbestos exposure. Maintenance crews and shipyard workers were particularly at risk since they often handled asbestos during repairs. Over time, even nontechnical staff faced exposure to old, crumbling materials.

Learn how to access benefits available to veterans affected by an asbestos-related illness.

Get Help NowCompensation for Navy Veterans Exposed to Asbestos

There are a number of options available for Navy veterans seeking financial assistance for costs associated with mesothelioma. Veterans facing a diagnosis as a result of military asbestos exposure are entitled to file a VA claim for benefits. There are also survivor benefits for spouses of veterans who died of service-related cancer.

Other mesothelioma compensation options include asbestos trust funds and filing a legal claim. Veterans don’t sue the Navy. Instead, they sue companies that made asbestos products used on Navy ships. Many of these lawsuits win, leading to payments that cover medical bills, travel costs for treatment and lost wages.

Mesothelioma Compensation for Navy Veterans

- Asbestos trust funds: Bankrupt companies established these funds for those who develop mesothelioma from their products. Legal claims can be processed through individual trust funds rather than in the traditional court system.

- Personal injury claims: People with mesothelioma pursue these lawsuits to seek compensation from companies responsible for their asbestos exposure.

- VA claims: Veterans diagnosed with mesothelioma or other asbestos-related diseases may qualify for disability compensation or benefits through the Department of Veterans Affairs.

- Wrongful death claims: The estate of a deceased family member can initiate this type of lawsuit to seek compensation.

Navy veterans may be entitled to multiple types of mesothelioma claims. VA-accredited Patient Advocates can help you file your VA claims and connect you with a mesothelioma lawyer who has experience helping Navy veterans.

“The professionalism and expert advice The Mesothelioma Center extended to us was truly a blessing as we dealt with my father’s mesothelioma,” Steve Reeck, son of a military veteran tells us. “The advocacy group’s expert guidance and advice dealing with the Veterans Administration was a miracle for my family. Thank you for everything.”

Access Free VA Claims Assistance

Free Cancer Guide for Veterans

Find a Top Mesothelioma Doctor

Common Questions About Asbestos on Navy Ships

- What are the health risks associated with asbestos exposure on navy ships?

-

Asbestos exposure can cause restrictive and interstitial lung diseases, asbestosis, pleural plaques and mesothelioma cancer of the pleura and peritoneum. It can also cause cancers of the lung, bronchus, gastrointestinal tract, larynx, pharynx and urogenital system (except the prostate).

Answered By: Aaron Munz, Director of Veterans Department & Former U.S. Army Captain

- Are navy ship workers still at risk of asbestos exposure today?

-

Some older ships with keels laid before 1983 may still have some asbestos materials and equipment. Current regulations are stricter about its use and presence today. Asbestos must be clearly labeled now. Personnel who are required to work with asbestos equipment should receive training and personal protective equipment.

Answered By: Aaron Munz, Director of Veterans Department & Former U.S. Army Captain

- Did the Navy take any precautions to protect sailors from asbestos exposure?

-

Beginning in the late 1970s the Navy began replacing asbestos materials on ships where a suitable alternative existed. In the 1980s ships went through yard periods to remove and replace asbestos. Today, regulations require labeling and safe handling for any remaining asbestos in use.

Answered By: Aaron Munz, Director of Veterans Department & Former U.S. Army Captain?