Based on Your Reading:

Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

Shipyards used large amounts of asbestos to build vessels. Shipyard workers and Navy service members encountered dangerous levels of asbestos that made their jobs among the most at-risk occupations for mesothelioma and asbestos-related lung cancer.

Written by Aaron Munz • Edited By Walter Pacheco

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Munz, A. (2023, October 5). Asbestos Exposure in Shipyards. Asbestos.com. Retrieved April 19, 2024, from https://www.asbestos.com/shipyards/

Munz, Aaron. "Asbestos Exposure in Shipyards." Asbestos.com, 5 Oct 2023, https://www.asbestos.com/shipyards/.

Munz, Aaron. "Asbestos Exposure in Shipyards." Asbestos.com. Last modified October 5, 2023. https://www.asbestos.com/shipyards/.

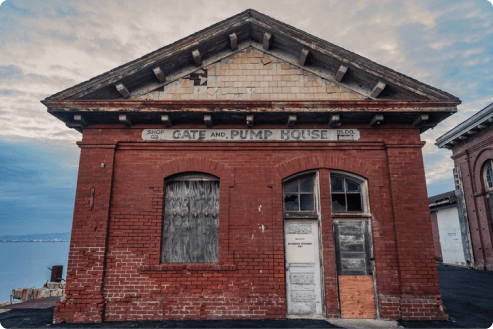

Asbestos resists corrosion and high temperatures, which made it an ideal material for use in the shipbuilding industry. Asbestos insulation was widely used on shipyard equipment, and asbestos corrugated sheeting was used to create shipyard buildings.

On ships, asbestos was used to prevent fires by insulating boilers, incinerators, hot water pipes and steam pipes. Asbestos dust tended to build up in inadequately ventilated areas, which led to exposure in shipyards and aboard vessels.

As the use of asbestos-containing products increased in the mid-20th century, occupational health experts began recognizing the diseases they could cause. Studies revealing the dangers of asbestos exposure date back to the 1940s, but it took decades for the U.S. government to acknowledge that inhaled asbestos fibers could persist inside the body, ultimately creating health issues.

By the 1960s and ’70s, the government took the health effects of asbestos more seriously. The massive task of removing asbestos from ships and replacing it with asbestos-free insulation began then, but the job has yet to be completed.

Ships decommissioned in shipyards today continue to contain old legacy asbestos products. Some of the materials were temporarily encapsulated to reduce the risk of exposure, but it creates an exposure hazard for decommissioning workers.

In 1943, one in 500 shipyard workers was an asbestos insulator. The job required them to handle asbestos directly by cutting, sanding and fitting insulation to various components of ships.

The U.S. Navy used asbestos materials on ships long before World War II. In 1922, the Navy created a specification requiring asbestos to construct all new submarines.

The Navy used more asbestos products than any other military branch. Asbestos was considered essential to use on vessels before its dangers were known because it naturally resisted saltwater corrosion and effectively prevented fires.

In 1932, 197 million pounds of asbestos were consumed annually in the U.S. Consumption drastically increased to 633 million pounds by 1937.

The American government classified asbestos as a critical material in 1939 and began stockpiling it. Worldwide demand for asbestos began to outpace the available supply. A significant amount of this supply found its way to shipyards across the U.S.

The Navy mandate to use asbestos in shipbuilding put millions of people at risk of exposure to asbestos. During World War II, approximately 4,500,000 men and women worked in shipyards where asbestos exposure risk was high.

Specific jobs required shipyard workers to handle asbestos products directly. These jobs included shipfitters, machinists, maintenance workers, pipefitters, electricians, boilermakers and painters.

Shipyard workers encountered asbestos even if they didn’t directly handle contaminated products. Cutting, sanding and fitting asbestos products around pipes, boilers and other structures released microscopic fibers into the air, where they could circulate throughout shipyards and vessels undergoing construction, renovation or decommissioning.

After World War II, the estimated number of shipyard workers declined from 1,700,000 in 1943 to about 200,000. The shipyard worker population remained at this level until 1976, fluctuating slightly with economic conditions and changing shipbuilding practices.

Get Your Free Mesothelioma Guide

Find a Top Mesothelioma Doctor

Access Help Paying for Treatment

As of March 2021, the U.S. was home to more than 154 shipyards actively building vessels and more than 300 shipyards engaged in repairs and decommissioning.

During the Emergency Shipbuilding Program from 1940 to 1945, more than 50 shipyards throughout the country participated in the war effort and asbestos use was mandated.

Home to the Pacific Coast’s first dry dock and the third-longest coastline in the United States, it’s no surprise that California is a leading state for shipyard asbestos exposure.

California’s abundant natural asbestos deposits and countless shipyards contribute to the state’s No. 1 ranking in the United States for mesothelioma and asbestosis deaths.

The New York Naval Shipyard, also known as the Brooklyn Navy Yard, was established by the government in 1801 and produced countless historic vessels. Though it was decommissioned in 1966, decades of asbestos exposure were reported at the site’s pipe shop, boiler shop, power plant, foundries, shipways and dry docks.

New York shipyards were among many locations in the state known for asbestos exposure. New York City courts had to develop the New York City Asbestos Litigation division to handle asbestos lawsuits associated with old factories, buildings and shipyards.

Located in the northwestern region of Washington, Puget Sound was bustling with naval shipbuilding activity during World War II. The Bremerton Naval Shipyard, which covers more than 1,300 acres of the sound, is currently the largest shipyard on the West Coast. Reports on the dangers of asbestos exposure at Bremerton date back to the mid-1940s.

A government report on the health effects of asbestos exposure among workers at Bremerton from 1970 showed lung abnormalities on chest X-rays. Insulators and pipefitters were among the most affected, and boiler workers and clerical workers also developed lung abnormalities.

Oregon shipyards, such as the Albina Engine and Machine Works Shipyard, played a crucial role in the World War II shipbuilding effort. Albina also significantly boosted Portland’s economy and growth during the early 1900s, but not without consequences. Albina shipyard, Swan Island Shipyard and Astoria Voyage Repair Station were known sites of occupational asbestos exposure.

Several major shipbuilding companies operated a variety of shipyards throughout the United States. Todd Shipyards Corporation, for example, operated yards in Brooklyn, New York; Galveston, Texas; Houston; Seattle; San Francisco; Los Angeles and New Orleans. Following the February 2011 purchase of Todd by Vigor Industrial, these sites became collectively known as Vigor Shipyards.

Kaiser Shipbuilding Company ran another notable chain of shipyards. Kaiser owned seven along the West Coast, including four in California; one in Vancouver, Washington; and two in Portland, Oregon.

Decades worth of research has confirmed the detrimental effects of asbestos exposure in shipyards.

The varying degrees of risk reported in these studies result from the study groups’ exposure to different amounts and types of asbestos. Even short or long asbestos fiber lengths may affect the degree of risk a worker faces.

For example, researchers from the esophageal cancer study proposed that milled asbestos material may be why shipyard workers are at a higher risk for cancer. Milled asbestos, which is processed into longer-length fibers, was used in shipyards. These fibers are more likely to become trapped in human tissue than smaller fibers.

Although evidence suggests the Navy’s negligence led to cases of asbestos exposure, legislation called the Feres Doctrine prevents veterans from seeking government compensation through the court system. Fortunately, many veterans are eligible for disability compensation and health care benefits provided by the U.S. Department of Veterans Affairs.

Veterans who served in shipyards are eligible for VA benefits if they did not receive a dishonorable discharge and can prove their service exposure is the cause of their disease.

As shipyard workers and Navy personnel began developing asbestos-related diseases, they filed claims against asbestos companies seeking compensation for medical costs and lost wages.

As a result, asbestos product manufacturers filed lawsuits against the U.S. government over liability.

Ultimately, the manufacturers were held liable. Today, shipyard workers and veterans file mesothelioma claims against asbestos companies and trust funds, not the U.S. government.

In 1944, GAF Corporation, then known as the Ruberoid Corporation, was contracted by the Navy to insulate ships with asbestos products. Multiple Ruberoid shipyard workers developed asbestosis. GAF tried to escape liability, but the company was eventually held responsible.

GAF Corporation sued to be released from liability based on the results of several shipyard studies. A report from Defoe Shipbuilding in Michigan indicated high levels of amosite asbestos, while another from a Seattle shipyard found asbestos dust released from cutting operations was collecting on overhead rafters and was not regularly removed.

In July 1983, the Johns Manville Corporation accused the Navy of allowing “gross exposure to asbestos fibers” to occur in its shipyards, referring to a classified 1944 health survey conducted at Navy contractor Bath Ironworks showing asbestos was 10 times the recommended safety level. A company lawyer claimed the Navy bought asbestos from Africa and then profited from its sale to Johns Manville.

At the time of these allegations, the company was preparing to sue the U.S. government for approximately $1 million to recover damages paid to settle asbestos lawsuits. Johns Manville faced 20,000 lawsuits from people seeking nearly $40 billion in damages.

In addition to applying for VA benefits, many Navy veterans and former shipyard workers have turned to mesothelioma lawsuits to recover the costs associated with diagnosing an asbestos-related disease. Though the government cannot be held responsible for asbestos exposure, negligent manufacturers of asbestos-containing products often can.

According to a 2003 article published in The Wall Street Journal, claims filed by veterans exposed in military and shipyard construction made up 26% of cases of mesothelioma, 16% of lung cancer cases and 13% of disabling lung disease cases.

Shipyard workers who believe they may have been exposed to asbestos should tell their doctors and request health screenings for asbestos-related illnesses. Documenting your asbestos exposure history in case you develop a condition is also wise.

If you have legal questions about accessing compensation, it is best to speak with an expert mesothelioma attorney to understand your options based on your diagnosis and exposure history.

There is no ban on asbestos in shipyards in the U.S. The U.S. Environmental Protection Agency attempted to enact a full ban on all asbestos products for any application in 1989, but it was turned into a partial ban that included only six products.

Asbestos was used to build ships because it is naturally resistant to saltwater corrosion and effective at preventing fires on vessels. Asbestos insulation was also used on shipyard equipment, and asbestos sheets were used as an affordable option to construct shipyard buildings.

It is possible that shipyards may be actively importing asbestos gaskets or brakes, but this information is not currently available to the public and no U.S. agency is required to track asbestos imports. It is not likely that shipyards have imported asbestos products in recent years.

Your web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592