Manufacturers once commonly mixed asbestos into many types of mastics, sealants and cements used in construction and shipbuilding. Damage or renovation work can disturb and release toxic fibers from dried-out asbestos adhesives still present in millions of old structures.

Mixing asbestos fibers into natural and synthetic glues resulted in durable, nearly fireproof adhesives, sealants, bonders and joint fillers. Builders used adhesives for all types of permanent installation work.

Asbestos was also a primary ingredient in gunning mixes, a type of spray-applied powdered adhesive mixed with water as it’s applied. Before the mix is made into a paste, it comes in powder form packaged in bags. Asbestos fibers in opened bags could easily become airborne when measuring and mixing the gunning mix.

Though people once saw asbestos products as safe and reliable construction materials, they’re now a known health hazard. In 2019, the Environmental Protection Agency banned adhesives as part of its April 2019 final rule preventing already banned products from re-entering the market. Those banned products include spray-on adhesives with more than 1% asbestos and asbestos flooring felt adhesive.

Though asbestos adhesive manufacturing ended in the U.S. in the 1990s, these products remain in many parts of old buildings today. Asbestos sealants and adhesives may also be imported from other countries.

While not every brand of black mastic contained asbestos, the toxic mineral was a common additive in these adhesives until the 1990s. Asbestos-containing mastics include liquid construction mastics, conventional lime-type cements and synthetic plastic cements.

Heavy-duty adhesives are often referred to as mastics in the construction industry. They typically take the form of paste applied from a caulking gun or powder mixed and applied like cement. Different types of mastics used asbestos, and the most common was black mastic.

Asbestos black mastic is a dangerous material. A licensed asbestos abatement company is required to perform professional removal. Exposed asbestos black mastic isn’t safe to walk on, sand down or disturb in any way. Homeowners who encounter black mastic should contact an abatement company for professional asbestos testing.

Asbestos adhesives may still be found in old buildings and houses. Adhesives were used in many places. These include the floors, wall panels, interior fixtures, ceilings, roofs, air ducts, pipes and boilers and furnaces.

Asbestos adhesives were used to install wood floors, vinyl tiles and other types of flooring. Asbestos black mastic was one of the most common flooring adhesives.

Wallpaper and wall panels were commonly installed using asbestos adhesives. Removing old wall panels can leave behind the adhesive, often visible as brittle old daubs.

Asbestos adhesives were used in the finishes of countertops, cabinetry and other fixtures.

Ceiling tiles were once attached to the ceiling using glue pods containing asbestos. As time passed, these glue pods became fragile and, when touched or disturbed, released dangerous asbestos fibers into the air.

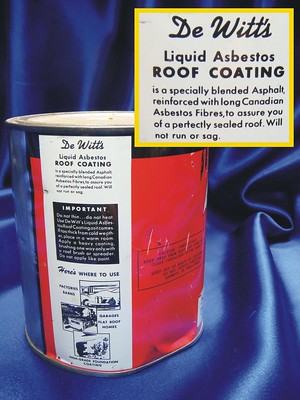

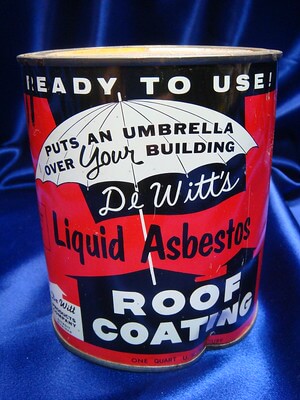

Asbestos was a common ingredient in plastic cement and sealants for rooftops. Over time, weathering exposes asbestos fibers, causing them to change color.

Even duct tape commonly contained asbestos fibers before the mineral’s toxicity was widely known.

Lagging is a method of protecting pipes from damage that involves wrapping them in strips of cloth coated with glue. In the past, asbestos glue was a popular choice for this purpose.

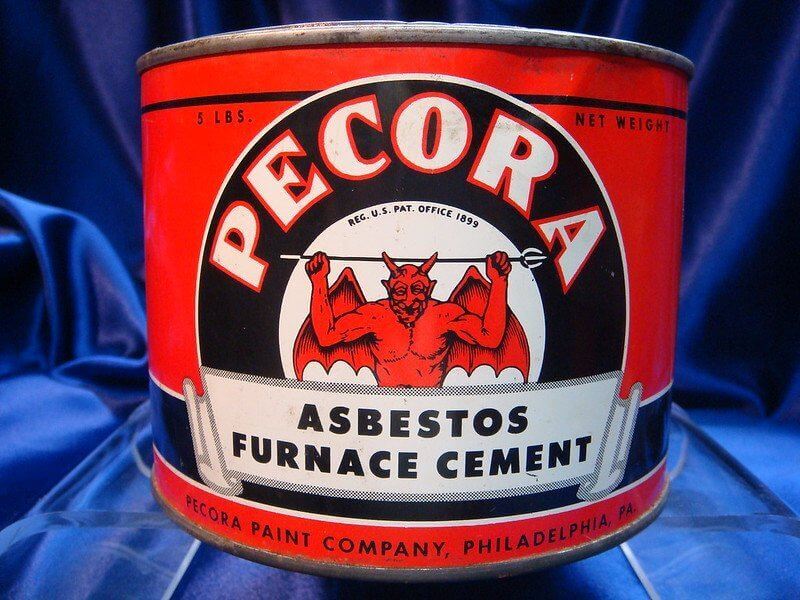

Special cement adhesives for high-temperature machinery, often called furnace cement, contained asbestos. Fireproof cement and joint compounds were used in industrial facilities and ships.

Asbestos adhesives can remain hidden under flooring, ceiling and roofing tiles for decades. The asbestos in these adhesives doesn’t become less dangerous with time. Homeowners who renovate parts of a home that contain asbestos adhesives remain at risk of exposure regardless of the age of the adhesive.

| Manufacturer | Brand |

|---|---|

| A.P. Green Industries | Steelplant Castable B, Castable Mix 204 |

| Amchem Inc. (Benjamin Foster Company) | Black Cat Roof Coating |

| Armstrong World Industries | S-89 Adhesive, S-90 Adhesive |

| Celotex Corporation | Carey Fibrous Adhesive, Careytemp Adhesive |

| Combustion Engineering Inc. | Stick-Tite Insulating Cement, WeatherKote Protective Duriseal |

| Empire Ace | Stic-On Cement |

| Fibreboard Corporation | Hydroseal |

| Georgia-Pacific Corporation | Triple Duty Joint Compound |

| Harbison-Walker Refractories Company | H-W Lightweight Castable #10 |

| Minnesota Mining and Manufacturing Company | 3M Adhesive, 3M Caulk, 3M Cement |

| Mobile Oil Corporation | Armorcote Adhesive, Dum-Dum Adhesive |

| National Gypsum Company | Gold Bond All-Purpose Joint Compound, Gold Bond Adhesive |

| North American Refractories Company | Narcocast, Narcocrete, Narcolite |

| Johns Manville | Asbestogard Adhesive, Duxseal |

For example, Armstrong World Industries made adhesive and flooring materials with asbestos. Celotex made adhesive and roofing shingles with asbestos. Johns Manville made many different asbestos construction materials and asbestos adhesives to adhere them securely.

Other companies manufactured asbestos adhesives for a wide range of purposes. For example, Pecora made adhesive for fireplaces and furnaces, while Crown Cork and Seal made adhesives for pipes.

Owens Corning made asbestos cement for insulation and mastic for tiles. Uniroyal B.F. Goodrich made adhesive for machine parts on automobiles and airplanes.

People exposed to asbestos may develop asbestos-related diseases such as lung cancer, mesothelioma and asbestosis. The risk of exposure is significant among people who worked directly with asbestos adhesives.

Doctors treat the above cancers with chemotherapy, radiation therapy and surgery. They use medication and different types of therapy for benign conditions.

Workers who constructed, renovated or demolished old buildings are at risk of exposure to asbestos in adhesives. Grinding, drilling, cutting or abrading asbestos adhesives can release asbestos fibers into the air, which workers may then inhale.

Occupations Exposed to Asbestos Adhesives

Other workers at risk include plumbers, electricians, flooring and roofing installers. Proper protective equipment and safety protocols help minimize risks and protect workers from these hazardous materials.

Thousands of workers have filed lawsuits against asbestos adhesive manufacturers. They seek compensation for medical costs and suffering related to asbestos diseases.

In one notable asbestos adhesive lawsuit in 2006, U.S. Navy veteran Joseph Garza filed a lawsuit against Asbestos Corporation Ltd. Garza developed asbestosis using the company’s asbestos adhesive cement to repair boilers on the USS Randall and the USS Agerholm for nearly 10 years. Because the company didn’t issue any warnings over the asbestos in its product, Garza didn’t take any precautions against breathing in the dust or getting it on his clothes and hair. The jury in his case ruled the company was responsible.

In the 1990s, two engineers filed lawsuits against NARCO, claiming they developed mesothelioma using the company’s gunning mix. Frederick Moss worked for Alabama Power Company and Martin Easter worked for U.S. Steel. Both were exposed to high levels of asbestos dust using NARCO gunning mix products, and they were never advised to wear protective gear. The jury found in favor of the plaintiffs, Moss, Easter and a third plaintiff who suffered from asbestosis.

Many companies in the asbestos industry have established trust funds as part of bankruptcy reorganization plans to settle claims with claimants. These trusts settle personal injury and wrongful death claims resulting from asbestos exposure connected to bankrupt companies.

For instance, NARCO emerged from bankruptcy in 2008, funding the North American Refractories Company Asbestos Personal Injury Settlement Trust with $6.32 billion. The National Gypsum Company Bodily Injury Trust has paid more than $429 million in claims since 2004, including to people exposed through Gold Bond adhesive products.

Other forms of asbestos compensation include VA claims, Social Security Disability and treatment and travel grants. Speak with a qualified mesothelioma attorney to learn more about your legal options for mesothelioma compensation.

Get help finding a top attorney who can get you the compensation you deserve.

Get Help NowOnly licensed asbestos abatement professionals should remove asbestos adhesives. These professionals wear protective gear and use high-efficiency particulate respirator masks to prevent inhalation of asbestos fibers. They also create special seals around the work area and take measures to prevent fibers from entering HVAC systems.

The adhesives often contain between 1% and 25% asbestos, depending on their purpose. As these products age, they can become brittle and break down, releasing tiny fibers into the air. Asbestos-containing seals may wear down, flake or peel away.

Black mastics in buildings constructed before the 1990s should always be professionally tested for asbestos. Sanding, scraping or grinding asbestos black mastic can release toxic dust into the air, endangering everyone in the building.

Chemical solvents can remove some asbestos adhesives, but these chemicals are not compatible with all types of adhesives, and they can damage or stain the subfloor. Check with the manufacturer about using chemical solvents.

The use of asbestos adhesives in the U.S. spans almost a century, with one of the earliest examples dating back to 1887 when the precursor of the Johns Manville Corporation began manufacturing fibrous adhesive cement that contained 20% asbestos. In 1906, the Philip Carey Manufacturing Company began selling an asbestos-based fibrous adhesive for general construction use.

Raw asbestos was dumped into a fluffing machine to separate the mineral fibers before combining them with resins or solvents in a batch-mixing tank to make many asbestos adhesives. This industrial process exposed adhesive factory workers to clouds of inhalable asbestos dust. Spray-applied asbestos adhesives further endangered the health of the construction workers who applied them.

During World War II, the need for asbestos adhesives increased significantly. This was especially true in the building of Navy ships then, as fireproofing was a priority. After the war ended, civilian and military use of asbestos adhesives grew during the Cold War era.

In the 1950s, the National Gypsum Company created a new line of construction products called Gold Bond. They went on to become standard materials used throughout the construction industry.

By the mid-1980s, manufacturers were producing almost 10 million gallons of asbestos adhesives annually. Unfortunately, this led to asbestos-related cancers and other diseases. Because of the mounting lawsuits filed as people were diagnosed with serious asbestos-related diseases and changing regulations, most companies stopped adding the toxic mineral to their products.

Recommended ReadingYour web browser is no longer supported by Microsoft. Update your browser for more security, speed and compatibility.

If you are looking for mesothelioma support, please contact our Patient Advocates at (855) 404-4592

The Mesothelioma Center at Asbestos.com has provided patients and their loved ones the most updated and reliable information on mesothelioma and asbestos exposure since 2006.

Our team of Patient Advocates includes a medical doctor, a registered nurse, health services administrators, veterans, VA-accredited Claims Agents, an oncology patient navigator and hospice care expert. Their combined expertise means we help any mesothelioma patient or loved one through every step of their cancer journey.

More than 30 contributors, including mesothelioma doctors, survivors, health care professionals and other experts, have peer-reviewed our website and written unique research-driven articles to ensure you get the highest-quality medical and health information.

My family has only the highest compliment for the assistance and support that we received from The Mesothelioma Center. This is a staff of compassionate and knowledgeable individuals who respect what your family is experiencing and who go the extra mile to make an unfortunate diagnosis less stressful. Information and assistance were provided by The Mesothelioma Center at no cost to our family.LashawnMesothelioma patient’s daughter

Whitmer, M. (2025, May 6). Adhesives. Asbestos.com. Retrieved June 5, 2025, from https://www.asbestos.com/products/adhesive/

Whitmer, Michelle. "Adhesives." Asbestos.com, 6 May 2025, https://www.asbestos.com/products/adhesive/.

Whitmer, Michelle. "Adhesives." Asbestos.com. Last modified May 6, 2025. https://www.asbestos.com/products/adhesive/.

An occupational scientist or another expert who specializes in occupational hazards reviewed the content on this page to ensure it meets current scientific standards and accuracy.

Sean Fitzgerald, PG, is a research geologist specializing in asbestos environmental studies.

Our fact-checking process begins with a thorough review of all sources to ensure they are high quality. Then we cross-check the facts with original medical or scientific reports published by those sources, or we validate the facts with reputable news organizations, medical and scientific experts and other health experts. Each page includes all sources for full transparency.

Please read our editorial guidelines to learn more about our content creation and review process.